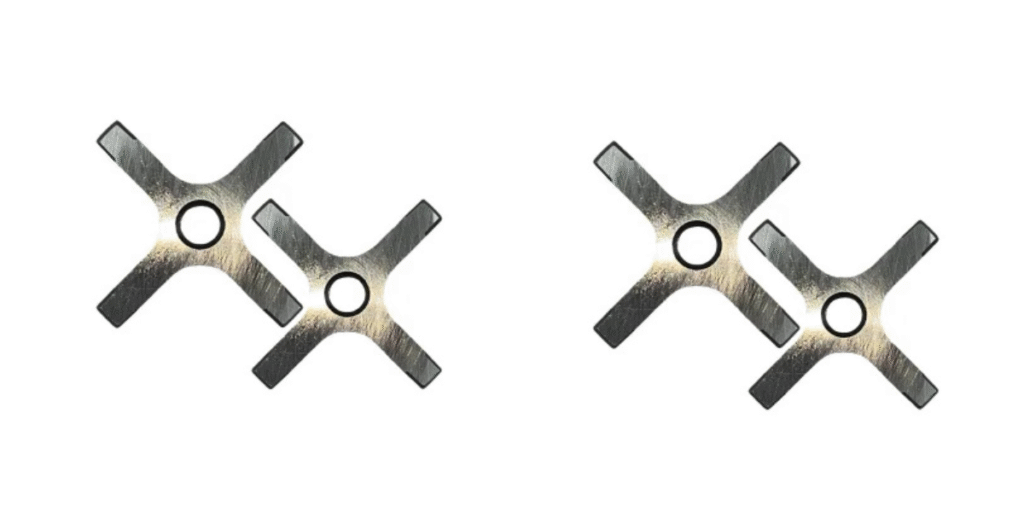

Cross Transmission Forging in Maharashtra

Introduction

An Indian forging company, SGEI Forgings Pvt.ltd. is a top manufacturer and supplier of a variety of high-quality closed die forgings and rolled ring forgings. We have been in business for more than 50 years, and during that period we have delivered with passion, quality, and the ability to complete an order on time. Customers value our items because they perform well. We provide a variety of products, including closed die forging and rolled ring forging.

Forged components are essential to the performance, longevity, and safety of heavy machinery, automotive systems, and industrial equipment. Cross Transmission Forging is now one of the most important forging methods for creating sturdy and dependable transmission parts.One of India’s most industrialized states, Maharashtra, is home to cutting-edge forging firms like SGEI Forgings Pvt. Ltd., which specialize in superior Cross Transmission Forging solutions for a variety of sectors. We are the best Cross Transmission Forging Supplier.

What is Cross Transmission Forging

Transmission components that effectively transfer power inside mechanical systems are made using a method called cross-transmission forging. In order to achieve greater strength and durability, it entails shaping metal—typically steel or alloy—under extreme pressure. In contrast to casting or machining, forging improves the metal’s mechanical qualities and increases its resistance to impact, wear, and fatigue by refining its grain structure.Producing high-torque parts that can sustain large loads and strong rotational forces, such as gears, shafts, and cross joints, is the main goal of cross transmission forging. This makes it an essential method in the heavy machinery, agricultural, and automotive industries. We are the best Cross Transmission Forging Manufacturer.

Why Choose SGEI Forgings Pvt. Ltd

- Uncompromising Quality Control: Quality isn’t a step in our process; it’s embedded in every action. From the moment raw material enters our facility to the final dispatch, every component undergoes rigorous checks. We employ advanced testing methods, including ultrasonic testing and magnetic particle inspection, to detect even the most minor internal flaws. This ensures that every part you receive is flawless and ready to perform.

- State-of-the-Art Technology: The forging industry has evolved, and so have we. SGEI is equipped with modern forging presses, CNC machines, and sophisticated heat treatment furnaces. This technological edge allows us to maintain consistent dimensional accuracy and superior mechanical properties in every batch, giving you components that last longer and perform better.

- Deep Metallurgical Expertise: Forging is as much a science as it is an art. Our team includes seasoned metallurgists who understand the behavior of different steel grades under heat and pressure. This expertise allows us to recommend the right material and process for your specific application, ensuring optimal performance under the most demanding conditions.

- A Culture of Customer Partnership: We believe in building relationships, not just closing deals. We work closely with our clients to understand their unique challenges and requirements. Whether you need a standard component or a custom-designed solution, our engineering team is ready to collaborate and deliver exactly what you need.

- Technical Expertise: Forging is a science. Our team of experienced metallurgists and engineers doesn’t just follow blueprints; they collaborate with you to optimize designs for manufacturability and performance. We can advise on the best material grades, heat treatment processes, and finishing options to ensure your component performs flawlessly in its application.

- End-to-End Capability: We are a one-stop solution. Our capabilities extend beyond the forge shop to include in-house machining, heat treatment, and surface finishing. This vertical integration gives us complete control over the production process, ensures shorter lead times, and simplifies your supply chain logistics. You deal with one responsible partner instead of multiple vendors.

- Reliability You Can Build Your Business On: In industry, a delayed shipment can halt an entire assembly line. SGEI has built a reputation for rock-solid reliability and on-time delivery. Our efficient production planning and robust logistics ensure that you get what you need, when you need it, every single time. This reliability allows you to plan your own production with confidence.

- Cost-Effectiveness Beyond the Initial Price: While our initial quote might be competitive, our real value lies in the Total Cost of Ownership. A cheaper, sub-standard component can lead to machine failure, costly downtime, and safety hazards. By providing forged components that last longer and perform better, we help you avoid these hidden costs, making your operations more profitable over the lifespan of your equipment.

Applications of Cross Transmission Forgings

1. Automotive Industry

- Used in gear shafts, drive shafts, universal joints, and coupling parts.

- Provides superior fatigue resistance and mechanical strength for long-lasting vehicle performance.

2. Power Transmission Systems

- Forged components like cross joints, yokes, and spline shafts ensure smooth and efficient power transfer.

- These parts can handle high torque and variable loads, making them ideal for industrial power systems.

3. Heavy Machinery and Equipment

- Cross Transmission Forging is used in construction, mining, and agricultural machinery.

- Components such as spindles, crankshafts, and transmission gears require high impact strength and precision — achieved through forging.

4. Aerospace and Defense

- Forged transmission parts are preferred for aircraft systems due to their lightweight yet high-strength characteristics.

- Ensures reliability and safety under extreme working conditions.

5. Oil & Gas and Energy Sectors

- Forged shafts and connectors are used in drilling equipment, pumps, and turbines.

- High resistance to pressure and temperature makes forging ideal for these applications.

Table of Specifications Cross Transmission Forging

| Parameter | Specification Details |

|---|---|

| Product Name | Cross Transmission Forging |

| Material Used | Alloy Steel, Carbon Steel, Stainless Steel, EN8, EN19 |

| Manufacturing Process | Closed Die Forging / Open Die Forging / CNC Machining |

| Surface Treatment | Shot Blasting, Zinc Coating, Heat Treatment |

| Tensile Strength | 600 – 1200 MPa (as per grade) |

| Hardness Range | 20 – 45 HRC |

| Available Sizes | Custom sizes as per client drawing |

| Tolerance | ±0.05 mm to ±0.10 mm |

| Applications | Automotive, Agriculture, Industrial Machinery, Gears |

| Quality Standard | ISO 9001:2015 Certified |

| Supply Locations | Pune, Mumbai, Nashik, Aurangabad, Kolhapur, Nagpur |

| Brand | SGEI Forgings Pvt. Ltd. |

Benefits of Cross Transmission Forging

- Superior Structural Integrity: Forging eliminates internal voids, gas pockets, and inconsistencies that are common in cast parts. This creates a homogeneous structure, meaning the part is equally strong throughout its entire body.

- Longer Lifespan: Because they are stronger and more resistant to wear and fatigue, forged transmission components last significantly longer than their counterparts. This translates to better value for money and lower total cost of ownership for the end-user.

- Expertise in Metallurgy: Our team has deep expertise in selecting the right grade of alloy steel and applying the correct heat treatment processes. This ensures the final product has the exact mechanical properties—hardness, toughness, and wear resistance—required for its specific application.

- Customer-Centric Approach: We understand that every client has unique needs. We work closely with our customers, offering customized solutions and providing technical support to ensure our components integrate seamlessly into their assemblies.

- Reduced Downtime: Our reliable forged shafts minimize the risk of unexpected failures, keeping your customers’ operations running and protecting your brand’s reputation.

- Enhanced Performance: The superior strength of our components allows for smoother power transmission, which can lead to improved fuel efficiency in vehicles and better performance in industrial equipment.

- Enhanced Fatigue Resistance: Transmission parts undergo millions of stress cycles. Forging eliminates internal voids and porosity, giving the part a much longer lifespan and resistance to metal fatigue.

- Reliability and Safety: In critical applications like automotive, aerospace, and heavy machinery, component failure can be catastrophic. Forged parts offer the highest level of reliability.

- Material Efficiency: While the initial process is energy-intensive, forging produces a part that is very close to its final shape near-net shape resulting in less material waste compared to machining a part from a large solid block.

- Proven Performance & Durability: Our components are built to last. By using superior grades of steel and controlling the forging process meticulously, we ensure that our parts offer exceptional wear resistance, reduced downtime, and a lower total cost of ownership for your equipment.

Types of Cross Transmission Forging

1. Open Die Forging

- Open die forging, also known as free forging, involves deforming the heated metal between flat or simple-shaped dies. It is ideal for large or custom transmission parts that require high strength and flexibility in design.

2. Closed Die Forging

- Closed die (impression die) forging uses precision-shaped dies that enclose the metal. When pressure is applied, the metal fills the die cavity, creating complex shapes with excellent accuracy.

3. Hot Forging

- In hot forging, metal is heated above its recrystallization temperature. This process reduces the flow stress and allows the metal to be shaped easily without cracking.

4. Cold Forging

- Cold forging is performed at room temperature, which results in superior surface finish and dimensional precision.

5. Upset Forging

- Upset forging increases the diameter of the workpiece by compressing its length. It is widely used for manufacturing bolts, shafts, and transmission pins.

6. Precision Forging

- Precision forging is a modern method where components are forged to near-net shape, requiring little or no machining afterward.

Conclusion

Cross Transmission Forging plays a vital role in powering modern industries with high-strength, precision-engineered components. Maharashtra’s industrial ecosystem provides the perfect foundation for forging innovation, and SGEI Forgings Pvt. Ltd. stands proudly as one of the top contributors to this growth.

SGEI Forgings Pvt. Ltd. keeps raising the bar in the forging sector with its dedication to quality, performance, and client satisfaction. Our Cross Transmission Forged components are designed to provide quality and dependability, whether they are used for heavy engineering, automotive, or industrial applications.