Gear Blanks Manufacturer in Pune

Table of Contents

Introduction

An Indian forging company, SGEI Forgings Pvt.ltd. is a top manufacturer and supplier of a variety of high-quality closed die forgings and rolled ring forgings. We have been in business for more than 50 years, and during that period we have delivered with passion, quality, and the ability to complete an order on time. Customers value our items because they perform well. We provide a variety of products, including closed die forging and rolled ring forging.

Gears are essential parts in the complex field of mechanical engineering, where durability and accuracy are paramount. Gears are essential for transferring motion and power in anything from the biggest industrial apparatus to the tiniest timepiece. Every high-performance gear has a carefully made gear blank in its core, which serves as the base for precisely cutting the gear teeth.You need look no farther than SGEI Forgings Pvt. Ltd. for companies looking for a dependable and superior gear manufacturer in Pune. We are a top forging firm that is dedicated to quality, with a focus on producing excellent gear that satisfy the various demands of various industries. We are the best Gear Blanks Supplier.

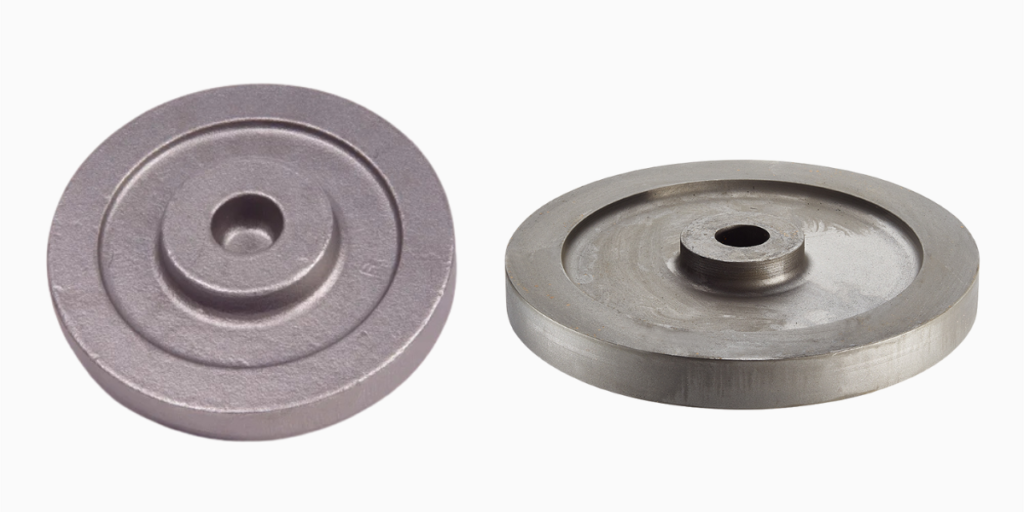

Understanding the Gear Blanks

Understanding the basic significance of gear in the manufacturing process is essential before exploring SGEI Forgings’ capabilities. In essence, a gear blank is a piece of metal that has already been forged or cut into a shape that nearly matches the finished gear. The basis material and shape for the ensuing gear cutting processes are provided by this first form. We are the best Gear Blanks Exporter.

Why Choose SGEI Forgings Pvt. Ltd

- Unwavering Quality Through Forging Expertise: We are experts in closed-die forging, a method that is known for creating gear blanks with remarkable dimensional correctness, strength, and longevity. Every gear blank we manufacture satisfies the highest quality standards thanks to the efforts of our skilled team of forging specialists. Your gears will have better mechanical qualities and a longer service life as a result of the forging process, which maximizes the material’s grain flow.

- Broad Variety of Materials: To satisfy the unique requirements of different applications, we work with a wide variety of premium steel alloys that have been carefully chosen. Our knowledge of material selection guarantees that the gear blanks you receive have the best possible balance of strength, hardness, resistance to wear, and other important characteristics.

- Precision and Accuracy: Every gear blank is guaranteed to have precise dimensions and tight tolerances thanks to our cutting-edge forging machinery and careful process control. Because of this accuracy, less extensive secondary machining is required, which saves you money and time.

- Personalization to Your Detailed Requirements: We are aware that each application has different needs. Our team at SGEI Forgings works directly with you to create gear blanks that completely match your design parameters, including size, shape, and material requirements. We provide bespoke forging solutions.

- Dedication to Excellence: At the heart of all we do is quality. Every gear blank that leaves our factory is guaranteed to satisfy the highest standards of excellence because we follow strict quality control methods throughout the manufacturing process.

- Dependability and On-Time Delivery: We recognize how crucial on-time delivery is to your production plan. We are dedicated to providing your gear blanks on schedule, every time, thanks to our effective manufacturing procedures and strong supply chain management.

- Competitive Pricing: We provide affordable prices without sacrificing the caliber of our output. Our cost-effective solutions for your gear blank needs are made possible by our effective forging procedures and optimal material use.

- Located in Pune, a significant industrial center: Gear blanks to meet the needs of our clients both domestically and internationally. No matter where you are, our effective logistics network guarantees prompt delivery to your address.

- Prioritize Long-Term Collaborations: We are committed to establishing enduring bonds with our clients based on mutual success, trust, and dependability. We are dedicated to become your reliable gear manufacturing partner rather than merely a supplier.

Applications of Gear Blanks

- Transmission Systems: Gear blanks for bevel, helical, and spur transmission gears that guarantee effective and seamless power transfer in buses, trucks, and cars. Forged blanks’ exceptional strength and resilience are essential for enduring the harsh circumstances found in a car’s transmission.

- Differential Gears: Forged blanks for differential gears, which are necessary for cornering because they enable the wheels on an axle to revolve at separate speeds. These gears’ accuracy guarantees the best possible vehicle handling and stability.

- Steering Systems: Reliable and rapid steering control is provided by gear blanks for power steering devices.

- Engine Parts: Timing gear blanks and other engine-related gears that need to be extremely precise and long-lasting.

- Gearboxes: Forged blanks for a variety of industrial gearboxes used in manufacturing equipment, power generation, and material handling, among other applications. Strong and dependable gears are necessary for these gearboxes, which frequently run under severe loads.

- Compressors and Pumps: Gear blanks for the gears that transmit power reliably and efficiently in compressors and pumps.

- Agriculture Equipment: Gear blanks for gears that are used in harvesters, tractors, and other pieces of equipment where toughness and resilience to adverse working circumstances are essential.

- Wind Turbines: The main gearboxes of wind turbines use large forged gear blanks to transform the rotor blades’ slow rotation into a faster speed that can be used to generate electricity. These devices need to be able to endure severe weather and function dependably for long stretches of time.

- Hydroelectric electricity Plants: Gear blanks for hydroelectric turbines and associated machinery that generate electricity efficiently.

Specifications Table of Gear Blanks

| Specification | Details |

|---|---|

| Product | Gear Blanks |

| Manufacturing Method | Hot Forging / Closed Die Forging |

| Material Grades | EN8, EN9, EN19, EN24, SAE 4140, SAE 8620 |

| Outer Diameter | 50 mm to 800 mm |

| Inner Diameter | As per client specification |

| Thickness / Length | 10 mm to 300 mm |

| Tolerance | ± 0.5 mm (or as per drawing) |

| Surface Finish | Machined / As Forged |

| Hardness | 28 – 32 HRC (after heat treatment) |

| Supply Condition | As Forged / Normalized / Heat Treated |

| Applications | Automotive, Heavy Machines, Gearboxes |

| Customization Available | Yes |

| Minimum Order Quantity | Flexible as per client needs |

| Delivery Time | 2–4 weeks |

| Location | Pune, Maharashtra, India |

| Certification | ISO Certified |

Types of Gear Blanks

- Spur gear blanks are the most widely used kind of gear; their teeth are oriented parallel to the rotational axis. Spur gear blanks from SGEI Forgings come in a variety of sizes and materials, making them appropriate for a broad range of power transmission applications.

- Helical Gear Blanks: The teeth of helical gears are angled with respect to the rotational axis. When opposed to spur gears, this design enables quieter and more seamless operation. To satisfy particular application needs, SGEI Forgings produces helical gear blanks with exact helix angles.

- Bevel Gear Blanks: The purpose of bevel gears is to transfer power between shafts that intersect. To meet a range of angle and load requirements, SGEI Forgings manufactures bevel gear blanks in three different configurations: straight, spiral, and hypoid.

- Worm Gear Blanks: A worm, which resembles a screw, meshes with a worm wheel to form a worm gear. Usually, they are applied to high reduction ratios. Worm wheel blanks with accurate tooth profiles are produced by SGEI Forgings to guarantee effective worm meshing.

- Internal Gear Blanks: Internal gears mesh with external gears and have teeth on their inside surface. Internal gear blanks that meet certain dimensional specifications can be produced by SGEI Forgings.

- Ring Gear Blanks: Often seen in planetary gear systems, ring gears are large-diameter internal gears. For demanding applications, SGEI Forgings produces ring gear blanks that are sturdy and precisely dimensionally exact.

- Splined Shaft Blanks: Although they are not quite gears, splined shafts are frequently essential to gear-based power transmission systems. Additionally, forged splined shaft blanks with exact spline profiles are available from SGEI Forgings.

- Custom Gear Blanks: SGEI Forgings specializes in creating custom gear blanks according to customer specifications, drawings, and material requirements since it understands that certain applications call for special gear designs.

Conclusion

Gears are the vital parts that propel motion and power in the complex world of machinery. The quality of the blank is the cornerstone of a long-lasting and high-performing piece of equipment. One of Pune’s top producers of gear blanks, SGEI Forgings Pvt. Ltd., offers a compelling blend of superior quality, cutting-edge technology, customizability, and a strong dedication to client satisfaction. We are the best Gear Blanks Manufacturer in Maharashtra.

By selecting SGEI Forgings Pvt. Ltd. as your partner, you are investing in the dependability, effectiveness, and lifespan of your machinery rather than only sourcing a component. Discover how superior forged gear blanks can improve your operations by taking use of the SGEI use. To discuss your unique needs and start your road toward accuracy and performance, get in touch with SGEI Forgings Pvt. Ltd. right now.