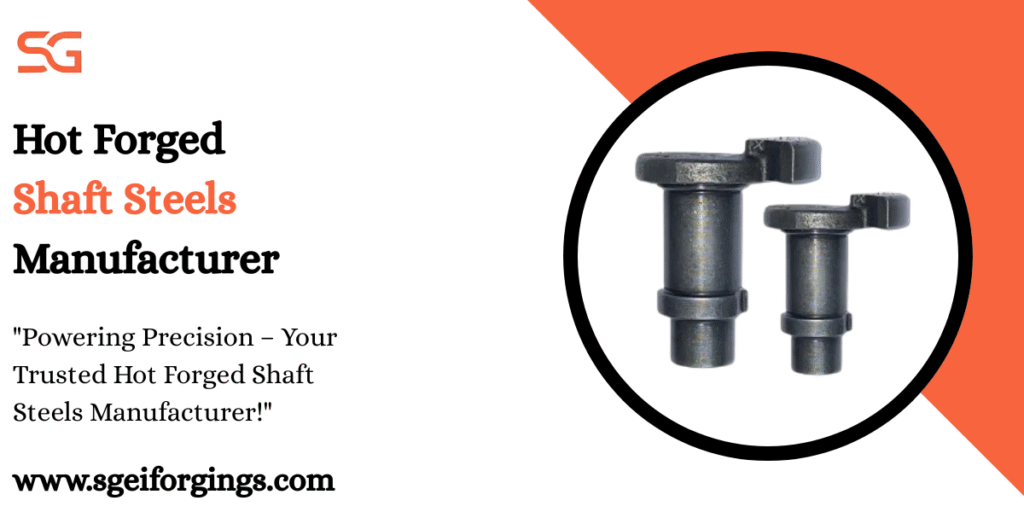

Hot Forged Shaft Steels Manufacturer

Introduction

An Indian forging company, SGEI Forgings Pvt.ltd. is a top manufacturer and supplier of a variety of high-quality closed die forgings and rolled ring forgings. We have been in business for more than 50 years, and during that period we have delivered with passion, quality, and the ability to complete an order on time. Customers value our items because they perform well. We provide a variety of products, including closed die forging and rolled ring forging.

Hot forged steel shafts stand out as a pillar of engineering excellence in the industrial production sector, where strength, durability, and dependability are not only desirable but necessary. From the tiniest engines to the biggest industrial turbines, these essential parts form the foundation of innumerable devices. However, what is hot forging exactly, and why does it result in a better shaft than its alternatives? The technique, advantages, and reasons why businesses like SGEI Forgings Pvt. Ltd. have mastered the art of producing components that satisfy the highest requirements are all covered in this article’s exploration of the intriguing world of hot forged shaft steels. Hot Forged Shaft Steels Supplier.

Why of Hot Forged Shaft Steels

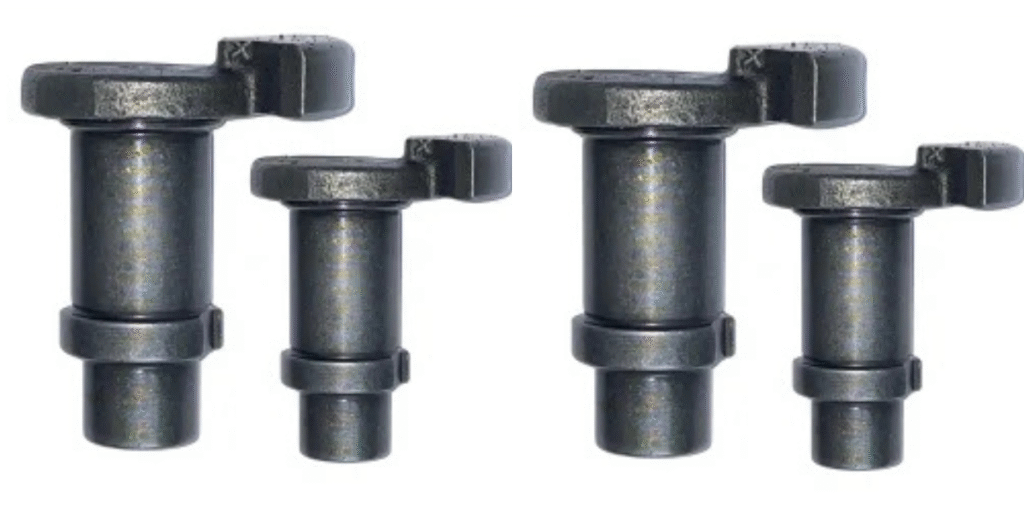

One must first comprehend the manufacturing process in order to fully appreciate a hot forged steel shaft. One of the earliest methods of shaping metal is forging, which uses localized compressive pressures that are usually applied with a press or hammer. As the name implies, hot forging is carried out at a high temperature above the recrystallization point of the metal. This temperature is typically between and for steel.The steel becomes extremely pliable at these high temperatures, making shaping it quite simple. A steel billet, the raw material, is heated before being put under tremendous pressure inside a die. Here’s where the magic takes place. Hot Forged Shaft Steels Exporter.

The steel’s interior structure is radically altered by the compressive force of the forging process. The forging process refines the steel’s grain structure, in contrast to a cast or machined object, which may have internal flaws such cavities and a coarse grain structure. The initial coarse grains are broken up and replaced with a much finer, more homogeneous grain structure.

Why Choose SGEI Forgings Pvt. Ltd

- Unwavering Precision and Quality: At SGEI Forgings, quality is the cornerstone of their operations and not just a catchphrase. They use cutting-edge forging machinery and a strict quality control procedure that complies with global norms. To make sure it satisfies and surpasses the needs of the client, every shaft is put through a battery of tests, including metallurgical analysis, non-destructive testing, and dimensional checks. Because of their dedication to accuracy, you will receive a product that fits and functions properly.

- A Vast Variety of Material Expertise: SGEI Forgings has worked with a wide variety of steel grades for a long time. They have the expertise and capacity to provide the appropriate product, regardless of whether your application asks for corrosion-resistant stainless steel for maritime settings or high-strength alloy steel for heavy machinery. They can help you choose the best material to meet your operating needs by guiding you through the selection process.

- Customized Solutions for Every Need: SGEI Forgings is aware that every project is different. They are quite good at offering specialized forging solutions. From the design stage to the finished product, their team of talented engineers collaborates directly with clients, providing technical assistance and a thorough grasp of production viability. The final product will be optimized for performance, cost-effectiveness, and manufacturability thanks to this cooperative approach.

- Emphasis on Client Satisfaction: SGEI Forgings places the client at the center of all they do. Dependability, open communication, and prompt delivery are the cornerstones of their reputation. They attempt to offer a smooth and effective experience from the first inquiry to post-delivery assistance since they recognize the significance of project timeframes.

- Proven Track Record: SGEI Forgings has a lengthy list of happy customers in a variety of industries, such as general engineering, oil and gas, power generation, and automotive. They have a track record of producing hot forged shafts that are dependable, long-lasting, and of excellent quality. Their knowledge and commitment are demonstrated by the fact that their goods power systems and machines all around the world.

- Advanced Manufacturing Technology: To guarantee accuracy and effectiveness in every forging project, we integrate cutting-edge technology with our vast experience. Our dedication to innovation enables us to manufacture intricate geometries with exacting tolerances, continuously producing goods that surpass expectations.

- Customer-Centric Service: We are committed to establishing enduring bonds with our customers. Our staff is committed to comprehending your unique needs and completing your purchase each and every time. What our customers value most about our goods is their excellent performance and dependability.

- Extensive Product Offering: Precision closed die forgings and rolled goods are among the many forgings in which we specialize. Because of our adaptability, we can create a wide range of components and meet individual customer requirements, making us a one-stop shop for all of your forging requirements.

Applications of Hot Forged Shaft Steels

1. Automotive Industry

- Hot forged shafts are used in engines, gearboxes, and axles where reliability and performance are critical.

2. Agricultural Equipment

- From tractors to harvesters, forged shafts help in managing the heavy-duty load and long working hours of farm machinery.

3. Power Transmission

- Forged shafts are a key component in industrial gear systems, conveyors, and wind turbines, enabling smooth transmission of mechanical power.

4. Marine and Shipbuilding

- Propeller shafts and drive shafts used in ships are hot forged to withstand the corrosive and high-load marine environment.

5. Railway and Metro Systems

- Forged shafts ensure the high strength required for wheel assemblies, braking systems, and traction motors.

Industrial Pumps & Compressors

- Shafts used in these machines face high pressure and rotating stress. Hot forging ensures durability.

Construction Equipment

- Forged shafts support high-impact operations in bulldozers, cranes, and excavators.

Shipbuilding & Marine Engineering

- Propeller shafts and engine parts in ships must resist corrosion and load, which forged steels can handle well.

Table of Specifications Hot Forged Shaft

| Parameter | Details |

|---|---|

| Product | Hot Forged Shaft Steels |

| Shaft Length | Up to 6000 mm |

| Forging Capacity | Up to 2500 tons |

| Material Grades | EN8, EN19, EN24, 42CrMo4, SAE 4140, etc. |

| Heat Treatment Options | Normalized, Annealed, Hardened & Tempered |

| Surface Finish | Black, Turned, or Machined |

| Tolerance Level | As per ISO H8 / H9 or customer specification |

| Ultrasonic Testing | ASTM A388 or customer standard |

| Production Volume | Single piece to bulk quantity |

| Packaging | Wooden boxes or as per customer requirement |

Advantages of Hot Forged Shaft Steels

- The greatest benefit is superior strength and durability. The steel’s interior grain structure is straightened and improved throughout the hammering or pressing process. This produces an uninterrupted, continuous grain flow that adheres to the shaft’s form. Imagine it as a dense, intricate web of fibers. For sections that are subjected to large loads on a regular basis, this structure makes the shaft extremely strong, tough, and resistant to fatigue, impact, and stress.

- Improved Mechanical Properties: Internal flaws that can weaken a cast item, like as voids and porosity, are removed during the forging process. Additionally, it enhances the steel’s metallurgical qualities, increasing its resistance to deterioration. For safety and operational effectiveness, this results into a longer service life and fewer breakdowns.

- Long-Term Cost-Effectiveness: Although a forged part may occasionally cost more to make initially than a cast one, there are substantial long-term savings. Forged shafts need minimal upkeep and repair since they are so dependable and long-lasting. Over the course of the machinery’s life, this improves return on investment by lowering repair costs and downtime.

- Design Versatility: From tiny parts to enormous industrial shafts, hot forging enables a broad range of sizes. Additionally, it’s a versatile method that can adapt to diverse steel grades, such as alloy, carbon, and stainless steel, to satisfy the unique requirements of varied applications.

- Better Machinability: A hot forged shaft is easier to manufacture because of its uniform and finely grained structure. This can increase the efficiency of the production process by cutting down on the time and expense of finishing procedures.

- Enhanced Ductility: The steel becomes less brittle or more ductile after hot forging. This is an essential safety feature because it prevents the shaft from catastrophically breaking under excessive strain by allowing it to flex or deform slightly.

- Cost-effective and Effective: Hot forging is a near-net-shape technique, even though heat is needed for the process itself. This significantly lowers the amount of material that must be removed by machining because the forged object is now considerably closer to its ultimate dimensions. This lowers production time and energy consumption in addition to material prices.

Types of Hot Forged Shaft Steels

1. Carbon Steel Forged Shafts

- These shafts are made from carbon steel and are widely used due to their strength and affordability.

Applications: Construction equipment, agriculture machinery, automotive parts.

2. Alloy Steel Forged Shafts

- These contain elements like chromium, molybdenum, and nickel for improved properties like toughness, corrosion resistance, and hardenability.

Applications: Gears, crankshafts, axles, heavy-duty transmissions.

3. Stainless Steel Forged Shafts

Known for their corrosion resistance and strength, stainless steel shafts are used in environments where rusting is a concern.

Applications: Marine shafts, chemical processing units, food machinery.

4. Duplex and Super Duplex Steel Forged Shafts

- These special steels offer excellent resistance to corrosion and stress cracking, suitable for harsh environments.

Applications: Oil & gas, desalination plants, offshore equipment.

5. Tool Steel Forged Shafts

- Used for high-performance tools and dies, these shafts are extremely hard and resistant to wear.

Applications: Aerospace, defense, industrial tools.

6. Customized Forged Shafts

SGEI Forgings Pvt. Ltd. also provides custom-made shafts based on client specifications in terms of dimensions, materials, tolerances, and surface treatments.

Applications: Special-purpose machines, OEM components.

Conclusion

More than merely metal components, hot forged shaft steels serve as the foundation for innumerable devices and systems that we use on a daily basis. They have a strength and durability that no other production technique can match because to the hot forging process. Selecting a manufacturer with a track record of quality and an understanding of this complex process is essential to guaranteeing the success and security of your initiatives. Best Hot Forged Shaft Steels Manufacturer.

You need look no farther than SGEI Forgings Pvt. Ltd. for a partner who can fulfill this commitment. They are a leader in the industry because of their wealth of expertise, dedication to excellence, and emphasis on client happiness. Selecting SGEI Forgings is more than just purchasing a product; it means investing in a tradition of quality and the assurance that your parts are long-lasting.