Rolled Rings Forgings Manufacturer

Introduction

An Indian forging company, SGEI Forgings Pvt.ltd. is a top manufacturer and supplier of a variety of high-quality closed die forgings and rolled ring forgings. We have been in business for more than 50 years, and during that period we have delivered with passion, quality, and the ability to complete an order on time. Customers value our items because they perform well. We provide a variety of products, including closed die forging and rolled ring forging.

Rolled rings forgings are essential to the production of strong, long-lasting parts in the fields of engineering and metalworking. Industries include heavy machinery, power generating, automotive, aerospace, and defense all make extensive use of these parts. SGEI Forgings Pvt. Ltd. is a trustworthy partner if you’re searching for a rolled rings forgings manufacturer. With cutting-edge technology, years of experience, and a dedication to quality, SGEI Forgings is committed to producing products of the highest caliber. We are the best Rolled Rings Forgings Supplier.

What is a Rolled Ring Forging

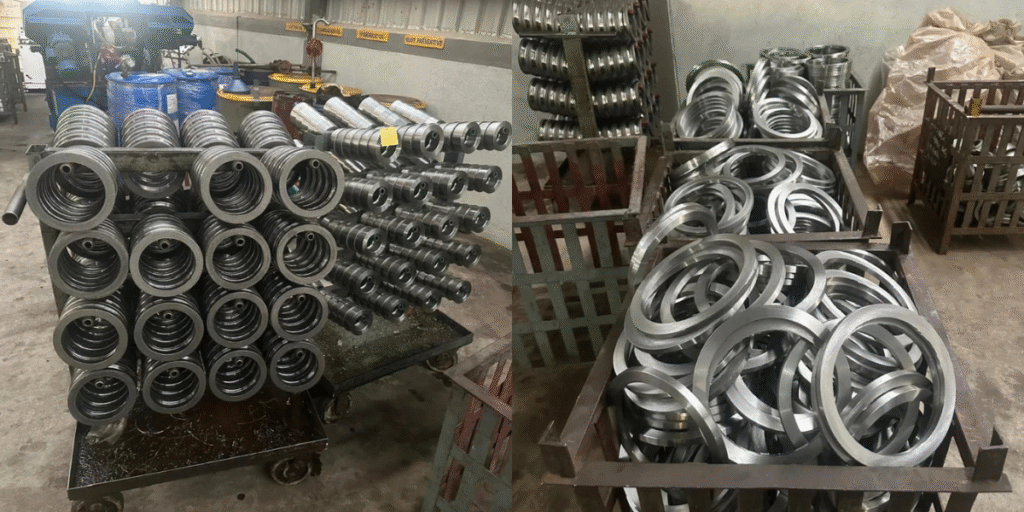

A rolled ring forging is in essence, a smooth, round piece of metal. It is not welded together from a plate, nor is it cast. Rather, a solid piece of metal is shaped into a ring using a highly regulated forging process.A billet is a solid cylindrical piece of metal that is used as the starting point for the process. Due of its high temperature, this billet becomes pliable and soft. We are the best Rolled Rings Forgings Exporter.

It is then given a doughnut shape by punching a hole through the middle. After that, this pre-form is put on a device known as a ring rolling mill. Similar to a potter’s clay, this machine uses an idler roll and a main roll to create pressure while the ring rotates. This pressure gradually increases the ring’s diameter while decreasing its wall thickness. The outcome A smooth, extraordinarily robust ring.

Why Choose SGEI Forgings Pvt. Ltd

- Unwavering Quality: At SGEI Forgings, we assure quality it’s not just a catchphrase. From the selection of materials to the last inspection, we follow strict quality control procedures all the way through the manufacturing process. This guarantees that each ring we ship is perfect and prepared for its intended use.

- Modern Technology: To guarantee the most accurate and efficient rolled ring forging process possible, we employ the newest equipment and technology. With the help of our machinery, we can create rings with excellent mechanical qualities and strict tolerances, providing you with reliable components.

- Trusted Expertise: Our team of highly qualified engineers and technicians has years of experience in the field and is capable of handling even the most challenging forging tasks. From choosing the right materials to the last step of finishing, we are masters in everything. We make certain that each ring we manufacture satisfies the highest quality requirements.

- Tailored Solutions to Meet Your Needs: We recognize that each project is different. For this reason, we collaborate closely with our clients to offer tailored solutions. We have the adaptability and know-how to satisfy your needs, whether they involve a particular material, a custom size, or a unique design.

- Experience and Expertise: We can handle challenging projects and produce goods that satisfy the highest requirements because to our extensive experience and thorough understanding of the forging process. Over the years, we have refined our abilities to guarantee that each and every forging we create demonstrates our commitment to quality.

- Customer-Centric Approach: We are committed to establishing enduring relationships with our customers. In order to provide specialized solutions and guarantee that your orders are delivered on schedule each and every time, we work closely with you to understand your unique demands. Our clients continuously express gratitude for our ability to fulfill complete requests with excellent performance.

- Versatile Production Capabilities: To satisfy your needs, we can create a large range of forgings. We have the equipment and know-how to provide, regardless of the material, size, or bespoke profile you need. Important industries including the oil and gas sector and mechanical services rely on our goods.

- Decades of Expertise: With almost fifty years of expertise, we possess the know-how to manage intricate projects and satisfy the most exacting requirements. We know how to deliver a product that surpasses expectations since we’ve seen it all.

- Dedication to Quality: For us, quality is more than simply a catchphrase; it is the cornerstone of our business. To guarantee that every forging we create is of the greatest caliber, we use strict quality control procedures at every stage of the process, from material selection to final inspection.

- Advanced Manufacturing Capabilities: To guarantee accuracy and efficiency, we use cutting-edge equipment and methods. Our skills enable us to create dimensionally correct and robust forgings, which will save you time and money on subsequent procedures.

Applications of Rolled Rings Forgings

1. Automotive Industry

- In the automotive sector, rolled rings are used in gears, wheel hubs, bearing races, and engine components. Their strength and durability enhance vehicle performance, ensuring safety and reliability under extreme conditions.

2. Aerospace Industry

- Aerospace components demand high-performance materials that can withstand high stress, temperature, and pressure. Rolled rings are used in aircraft engines, landing gear, and structural parts, offering excellent fatigue resistance and uniformity.

3. Oil and Gas Industry

- The oil and gas sector requires robust equipment capable of operating in harsh environments. Rolled rings are used in valves, flanges, drilling equipment, and pipelines due to their toughness and resistance to wear and corrosion.

4. Power Generation

- In power plants, rolled rings are critical for turbines, generators, and other rotating machinery. They ensure optimal performance, longevity, and minimal maintenance requirements.

5. Heavy Machinery

- Rolled rings are integral to construction, mining, and industrial machinery. Components like crane wheels, rollers, and couplings benefit from the high load-bearing capacity of forged rings.

6. Marine Industry

- Marine applications require materials that can endure harsh seawater conditions. Rolled rings used in propellers, ship engines, and other marine machinery provide strength, corrosion resistance, and long-term reliability.

Specifications Table of Rolled Rings Forgings

| Specification | Details |

|---|---|

| Material | Rolled Rings Forgings |

| Outer Diameter | 100 mm – 4000 mm |

| Inner Diameter | 50 mm – 3500 mm |

| Height/Thickness | 20 mm – 1000 mm |

| Weight | 5 kg – 5000 kg |

| Tolerance | As per ASTM, DIN, and customer requirements |

| Surface Finish | Machined, Forged, Polished |

| Standards | ASTM, ASME, DIN, ISO |

Benefits of Rolled Rings Forgings

- Superior Strength and Durability: A denser, more homogeneous structure is produced by the process, which also removes internal cavities. For components in high-stress applications, this results in a substantially stronger final product that is more resilient to impact and fatigue.

- Cost-Efficiency and Material Savings: The method of rolled ring forging uses very little material. Compared to cutting a ring from a plate or bar, there is a lot less waste because the beginning billet is scaled near to the finished output. Cost reductions are a direct result of this decrease in material waste.

- Better Performance: Compared to rings created using other techniques, forged rings can withstand more intense temperatures, pressures, and strains due to their improved mechanical qualities. They are a dependable option for crucial applications due to their consistent conduct under stress and heat.

- Versatility in Size and Material: Rings ranging in size from a few pounds to several tons can be produced using rolled ring forging. Additionally, a wide range of materials, such as carbon steel, alloy steel, stainless steel, and even specialty nickel-based alloys, can be employed in the process, enabling customizable qualities to satisfy particular industry needs.

- Decreased Machining Requirements: Post-forging machining is less necessary since the forging process yields a product with dimensions that are extremely near to the final required shape. This avoids material waste, saves time, and lowers production costs.

- Seamless Construction: Rolled rings are seamless, as opposed to rings that are cut from a plate and then welded. By doing this, weak points in the weld are eliminated, increasing the ring’s dependability and safety in high-stress applications.

- Better Heat Tolerance: Compared to other components, forged rings can withstand high temperatures and significant temperature changes because of their more homogeneous internal structure. Because of this, they are perfect for usage in demanding settings like aerospace and power generating.

- Consistency and Reliability: The forging process’s regulated environment guarantees constant quality and dimensional accuracy. This guarantees that every product satisfies stringent industry requirements and operates dependably in its intended application, thereby reducing the need for expensive and time-consuming rework.

Types of Rolled Rings Forgings

1. Ring Flanges

- Ring flanges are circular metal rings with a flat or raised face, used to connect pipes, valves, and other industrial components. They are essential in oil and gas, petrochemical, and chemical industries. SGEI Forgings Pvt. Ltd. manufactures ring flanges with precise dimensions and high-quality materials to ensure leak-proof connections.

2. Bearing Rings

- Bearing rings form the core part of bearings, providing smooth rotation and high load-carrying capacity. They are widely used in automotive, aerospace, and industrial machinery. With advanced forging techniques, SGEI Forgings Pvt. Ltd. ensures that bearing rings have exceptional hardness, wear resistance, and dimensional accuracy.

3. Gears

- Rolled ring gears are commonly used in automotive transmissions, heavy machinery, and wind turbines. These gears are stronger than cast or machined gears, providing longer service life. SGEI Forgings Pvt. Ltd. produces precision-rolled ring gears customized for specific torque and speed requirements.

4. Slewing Rings

- Slewing rings are large-sized rings used in heavy equipment such as cranes, excavators, and wind turbines. These rings are critical for rotational movement and heavy load handling. SGEI Forgings Pvt. Ltd. specializes in manufacturing slewing rings with superior toughness and fatigue resistance.

5. Clutch Plates

- Clutch plates are essential in automotive and industrial machinery, providing controlled torque transfer between shafts. Rolled ring forgings enhance the strength and reliability of clutch plates. At SGEI Forgings Pvt. Ltd., clutch plates are produced with strict quality control measures to ensure optimal performance.

6. Custom Rings

- SGEI Forgings Pvt. Ltd. also manufactures custom rolled rings according to specific client requirements. These can vary in size, thickness, and material composition, catering to unique applications in aerospace, power generation, and marine industries.

Conclusion

In today’s business, rolled ring forgings are essential parts because they offer the strength, dependability, and durability required for crucial applications. Selecting the appropriate partner is crucial when it comes to manufacturing these essential components. We are the Best Rolled Rings Forgings Manufacturer.

More than just a producer of rolled rings forgings, SGEI Forgings Pvt. Ltd. is a trusted partner dedicated to perfection, a quality enforcer, and an inventor. For your most challenging projects, SGEI Forgings offers unmatched performance and dependability because to our unique combination of experience, cutting-edge technology, strict quality control, and customer-focused service.