Sleeve Ring Forgings in Maharashtra

Introduction

An Indian forging company, SGEI Forgings Pvt.ltd. is a top manufacturer and supplier of a variety of high-quality closed die forgings and rolled ring forgings. We have been in business for more than 50 years, and during that period we have delivered with passion, quality, and the ability to complete an order on time. Customers value our items because they perform well. We provide a variety of products, including closed die forging and rolled ring forging.

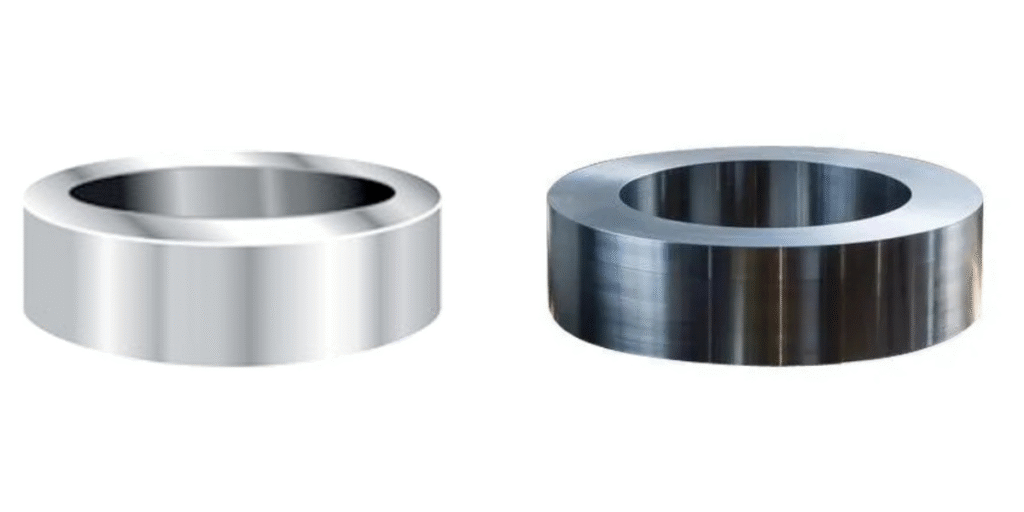

Component strength and dependability are non-negotiable in engineering and industrial applications. The sleeve ring forging is one such essential part, particularly in heavy-duty machinery. Although the name may sound complex, the idea is straightforward: it’s a metal ring that has been reinforced and molded by the forging process. Furthermore, Maharashtra is a major center for superior manufacturing when it comes to premium sleeve ring forgings. We are the best Sleeve Ring Forgings Supplier.

What Exactly are Sleeve Ring Forgings

Consider a donut-shaped chunk of metal. Now picture this donut being pounded, hammered, or rolled with tremendous force after being heated to a very high temperature. That’s what forging is all about. This method alters the metal’s interior structure in addition to shaping it. Forging removes internal flaws and produces a product that is incredibly strong, resilient, and stress-resistant by pressing the grain of the metal to match the contour of the part. We are the best Sleeve Ring Forgings Manufacturer.

One particular kind of forging that has a ring or hollow cylindrical shape is called a sleeve ring forging. Usually, a heated, pierced metal billet is set on a mandrel and rolled to increase its diameter and decrease its wall thickness. This technique is known as rolled ring forging. A seamless ring with exceptional mechanical and structural integrity is the end result.

Why Choose SGEI Forgings Pvt.ltd

- You Can Trust the Quality: We use premium-grade materials from India’s top steel manufacturers to make our forgings. To make sure every product satisfies your requirements, we employ sophisticated forging techniques and maintain a rigorous quality control procedure. You will receive parts that are not only robust but also have excellent dimensional correctness and a perfect finish thanks to our dedication to quality.

- Having worked in the forging sector for more than we contribute a wealth of expertise and experience to every project. We can offer solutions that are specifically designed to meet your needs because we are aware of the unique demands of different sectors. Our enduring presence is evidence of our enthusiasm, excellence, and dedication to prompt delivery.

- Broad Product Offering: Although we are experts in forging sleeve rings, we can also do a wide range of open and closed die forgings. Because of our adaptability, we can handle a wide range of your forged component requirements, from big industrial parts to smaller, more complex parts for the automobile industry.

- Customer-Centric Approach: We take great satisfaction in establishing enduring bonds with our customers. From the first stages of design to the last delivery, we collaborate closely with you to make sure your precise requirements are satisfied. Our objective is to offer a solution that supports the success of your company, not only sell a product.

- Modern Manufacturing Techniques: We can create sleeve rings with great precision and dimensional correctness thanks to our state-of-the-art forging tools and technology. From tiny batches to large-scale production, we can manage a variety of project requirements thanks to our sophisticated manufacturing skills.

- Team with Experience: Our team is made up of highly qualified engineers, technicians, and quality control specialists who have worked in the forging sector for a long time. Their knowledge guarantees that each forging satisfies the necessary requirements and quality standards.

- Customization Possibilities: We are aware that every application has different needs. SGEI Forgings provides specialized forging solutions that are suited to your particular requirements, taking into account tolerances, dimensions, and material choice. We collaborate closely with our clients to fully grasp their needs and provide solutions that go above and beyond.

- Competitive prices: We aim to provide competitive prices while upholding the best standards of quality. Our smart sourcing and effective manufacturing procedures allow us to offer affordable solutions without sacrificing the caliber of our forgings.

- Prompt Delivery: In the fast-paced industrial world of today, we recognize the value of prompt delivery. SGEI Forgings is dedicated to keeping your projects on track by adhering to predetermined delivery dates.

Application of Sleeve Ring Forgings

1. Valves and Valve Components

- Valve bodies, seats, and sleeves work under fluctuating pressure and corrosive fluids. Forged sleeve rings are used for valve stems, guide sleeves, and sealing surfaces because they resist erosion, maintain concentricity, and ensure long-term sealing integrity. In power plants, petrochemical refineries, and water treatment facilities across Maharashtra, forged sleeves contribute to leak-free, low-maintenance valve performance.

2. Pumps and Pump Casings

- Pumps handling slurry, hydrocarbons, or high-pressure fluids need wear-resistant, concentric sleeves to protect shafts and bearings. Forged sleeve rings used in pump bushings and bearing housings extend service life and reduce downtime. Mining, municipal waterworks, and chemical-processing plants benefit from these durable components.

3. Compressors and Rotating Equipment

- Compressors and turbines require precisely forged rings for rotor supports, bearing sleeves, and wear surfaces. The superior mechanical properties of forged rings resist cyclic loading and vibration, making them ideal for heavy industrial compressors used in refineries, gas processing, and large-scale HVAC systems.

4. Automotive and Heavy Vehicle Components

- Sleeve rings find use in axles, transmission components, and engine parts where wear resistance and dimensional stability matter. In Maharashtra’s automotive supply chain, quality forgings help manufacturers meet tight tolerances and long service intervals.

5. Oil & Gas Industry

- Downstream and upstream oil & gas equipment operate in harsh environments — high pressures, corrosive chemicals, and abrasive particulates. Forged sleeve rings in drill equipment, pipeline connectors, and valve assemblies provide the toughness and reliability the sector needs.

6. Marine and Offshore Applications

- Marine components require both corrosion resistance and toughness. Forged stainless-steel sleeve rings are used in propeller shafts, rudder assemblies, and other marine hardware where reliability at sea is non-negotiable.

7. Heavy Machinery and Construction Equipment

- Buckets, bearings, pivots, and hydraulic cylinder sleeves in construction equipment benefit from forged rings that stand up to impact, abrasion, and heavy cyclic loads. This reduces maintenance and keeps project timelines on track.

Table of specifications Sleeve Ring Forgings

| Item | Specification (short) |

|---|---|

| Material | Sleeve Ring Forgings |

| Main machines | Pre-cleaner, De-huller, Aspirator, Grader, Packing unit |

| Power requirement | 10–125 kW (depends on capacity) |

| Material of contact parts | Food-grade stainless steel (SS304) |

| Automation level | Semi-automatic to fully automatic PLC controls |

| Yield (typical) | 65–85% (varies by millet type & moisture) |

| Footprint | 15–200 sq.m (depending on capacity) |

| Warranty | 12 months on manufacturing defects |

| After-sales | Commissioning, training, spares available |

Benefits of Sleeve Ring Forgings

- Superior Resistance to Fatigue and Wear: The forging process strengthens the material’s structural integrity, making the rings far more resilient to fatigue, which is the weakening of a material brought on by repeated cycles of stress. Because of their extended longevity, they require less regular maintenance and replacement.

- Unmatched Durability and Strength: These rings are exceptionally durable due to their polished grain structure and absence of internal flaws. They are resistant to deformation and cracking even when subjected to high temperatures, tremendous pressures, and ongoing stress. In crucial applications where component failure can have disastrous results, such as oil and gas, power production, and aerospace, this is essential.

- Cost-Effectiveness: The first forging process is very efficient in terms of material utilization, despite its seeming complexity. In order to get their final shape, forged items frequently need less extra machining, which minimizes waste and lowers production costs overall.

- Versatility: To satisfy the unique needs of various industries, sleeve ring forgings can be produced from a broad range of materials, such as carbon steel, alloy steel, and stainless steel. From tiny parts to enormous rings for large machinery, they can be made in a variety of shapes and sizes.

- Dedication to Quality: We follow the most stringent quality control procedures. To ensure there are no internal flaws, every forging is put through a rigorous testing process that includes ultrasonic testing. Our clients are reassured by the great performance and dependability of our products.

- On-time Delivery: In the manufacturing industry, we are aware that time is money. We can deliver big orders on time because to our efficient procedures and reliable supply chain, which guarantees that your projects are completed on time.

- Customization and Capacity: We have the ability and know-how to complete any order, whether you require a basic sleeve ring or a specially made component. From the beginning to the end, our team will collaborate with you to make sure the finished product meets your needs.

Types of Sleeve Ring Forgings

Solid Ring Forgings

- A full circular ring forged from a solid blank. Used where high strength and uniformity are essential (bearing races, large flanges).

Seamless Sleeve Rings Hollow Forgings

- Forged as a hollow cylindrical part (sleeve). Common in piston sleeves, bearing housings, and coupling sleeves. Seamless design improves pressure containment and fatigue life.

Split Rings Two-Piece Sleeve Rings

- Made as two halves joined during assembly — useful for retrofits or where installation around an existing shaft is required.

Stepped Sleeve Rings

- Include internal or external steps for specific mounting or sealing arrangements. Often used in gearboxes and bearing seats.

Flanged Sleeve Rings

- Rings with one or more flanges for bolting or welding to other components. Widely used in piping flanges and valve bodies.

Customized Profile Rings

- Forged to an exact profile required for a unique application — can include grooves, counterbores, or tapped holes post-forging.

Conclusion

The unsung heroes of Maharashtra’s industrial environment are the forgings of sleeve rings. They are essential components in many different areas due to their important functioning and sturdy nature. Leading manufacturers of these essential components, such as SGEI Forgings Pvt. Ltd., greatly enhance the dependability and efficiency of machinery and equipment across the state.

As Maharashtra continues its journey of industrial advancement, the demand for high-quality sleeve ring forgings will only grow, and SGEI Forgings is well-positioned to meet this demand with its commitment to quality, innovation, and customer satisfaction. For your sleeve ring forging requirements, pick SGEI Forgings Pvt. Ltd. and see the impact that dependability and quality can have.