Forged Gear Components Manufacturer

Forged Gear Components Manufacturer/Forged Gear Components Supplier/Forged Gear Components Exporter/Best Forged Gear Components Manufacturer/Forged Gear Components/

Table of Contents

Introduction

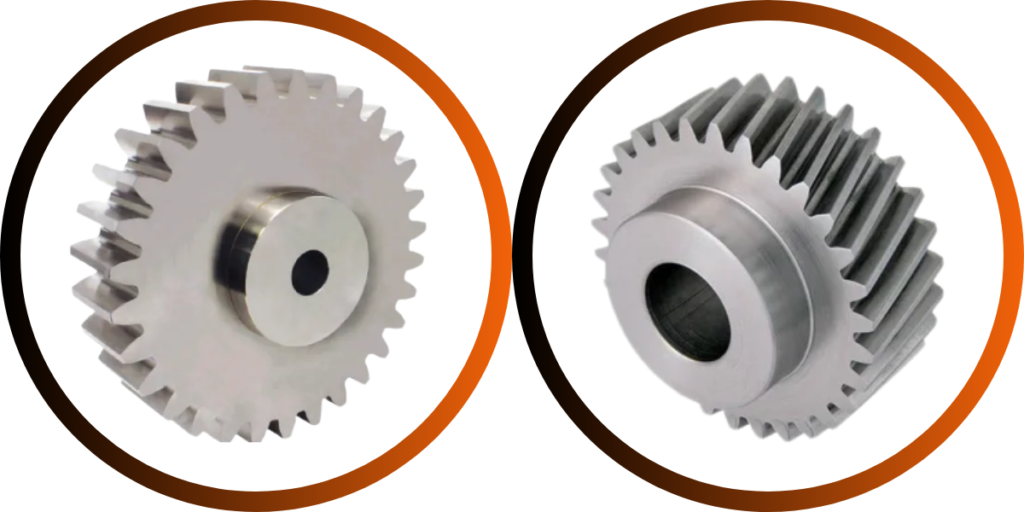

An Indian forging company, SGEI Forgings Pvt. Ltd. is a top manufacturer and supplier of a variety of high-quality closed die forgings and rolled ring forgings. We have been in business for more than 50 years, and during that period we have delivered with passion, quality, and the ability to complete an order on time. Customers value our items because they perform well. We provide a variety of products, including closed die forging and rolled ring forging. We are the best Forged Gear Components Manufacturer.

Two qualities that cannot be sacrificed in the fast-paced world of industrial manufacturing are strength and precision. The gear system is one of the most important components of many industrial vehicles, machines, and tools. In order to keep machines operating smoothly and efficiently, gears aid in the efficient transmission of power. But have you ever wondered how these gears are made? The forging process holds the key, and businesses like SGEI Forgings Pvt. Ltd. are leading the way in this technology.

We’ll delve completely into the world of forged gear components in this blog, including their significance across a range of industries, the production process, and the reasons SGEI Forgings Pvt. Ltd. is the best partner for premium forged components. This guide will explain everything you need to know in plain, understandable language, regardless of your background—engineering, procurement management, or simply a general interest in manufacturing.

What Are Forged Gear Components?

Let’s first divide forged gear components into two categories: forging and gears.

1. What Are Gears?

To transfer torque and motion between machine parts, gears—mechanical parts with teeth—mesh with other gear teeth. From the small gears in your wristwatch to the massive gears found in automobiles, wind turbines, and industrial machinery, they are present everywhere. In order to modify motion’s speed, torque, and direction, gears are essential.

2. What Is Forging?

The manufacturing process of forging involves heating and shaping metal with compressive force, usually with the aid of a press or hammer. By aligning the internal grain structure of the metal, the process strengthens it, giving the finished product greater strength, durability, and resistance to wear and tear.

Combining forging and gears results in forged gear components, which are made using the forging process and are therefore far stronger and more durable than those made using other manufacturing techniques like casting or machining.

Why Forged Gear Components Are Important

Due to their many advantages over other gear types, forged gear components are crucial in many industries. This explains why they are so important:

- Excellent Sturdiness and Power

By aligning the metal grains in the direction of the applied force, the forging process increases the material’s strength. For gears that must withstand high stress levels, like those found in cars, large machinery, and aerospace applications, this is especially essential. - Enhanced Efficiency

Because forged gears are more accurate and have superior mechanical qualities, they operate more smoothly, produce less noise, and are more efficient. This is particularly essential in sectors where performance is crucial, like the automotive and aerospace industries. - Resistance to Fatigue and Wear

Forged gear components are stronger and can endure harsher environments, such as high temperatures, heavy loads, and continuous use, without wearing out quickly. - Long-Term Cost-Effective

The longevity and dependability of forged components make them more cost-effective in time, even though they may initially cost more than cast or machined parts. Reduced maintenance expenses and downtime are the results of fewer malfunctions.

Industries That Depend on Forged Gear Components

Many different industries use forged gear components. These elements are essential in the following important sectors:

- Automobile Sector

Cars, trucks, and other vehicles’ gears must be able to withstand high torque and stress levels. Engines, differentials, and transmissions all use forged gear components to guarantee long-lasting and seamless function. - The Aeronautical Sector

Reliability and accuracy are essential for aircraft engines and control systems. For crucial aerospace applications, forged gears offer the strength and performance required. - Construction and Heavy Supplies

Strong gear systems are necessary for excavators, cranes, and other heavy machinery to manage the high loads and demanding operating conditions present on building sites. - Generation of Power

Gears are used to efficiently transfer energy in wind turbines, hydroelectric plants, and other power generation systems. These systems run dependably for extended periods of time thanks to forged gears. - The Marine Sector

The tools for ships and submarines must be able to survive the challenging marine environment. Components of forged gear can withstand the heavy loads commonly found in marine applications and are resistant to corrosion.

Why Choose SGEI Forgings Pvt. Ltd.: Best Forged Gear Components Manufacturer

The next query is: Why should you pick SGEI Forgings Pvt. Ltd. as your reliable manufacturer now that you are aware of the significance of forged gear components and the production process?

Delivering premium forged gear components that satisfy the highest industry standards is something we at SGEI Forgings Pvt. Ltd. take great pride in. We are the best Forged Gear Components Supplier. What makes us different from the competition is this:

- Unmatched Accuracy and Quality

Modern forging techniques and advanced machinery are used by us to create gear components with remarkable accuracy. Our stringent quality control procedures guarantee that every piece of machinery we produce satisfies exacting requirements and provides exceptional strength and performance. - Tailored Solutions

Every client is different, and we are aware that every industry has different needs. SGEI Forgings Pvt. Ltd. provides specialized forging solutions made to meet your unique requirements. We provide the gears you need for heavy machinery, automobiles, and airplanes. - Skilled Group of Professionals

Many years of experience are brought to the table by our team of highly qualified engineers and technicians. We keep up with the most recent developments in forging technology in order to offer creative solutions that satisfy our clients’ changing needs. - A Dedication to Sustainability

Responsible manufacturing is something we support. In order to ensure that we contribute to a sustainable future, our forging processes are made to minimize waste, optimize energy use, and lower our carbon footprint. - Dependable Service and On-Time Delivery

We are aware of how critical timely delivery of components is to businesses. Our dependable logistics and effective production procedures guarantee that your orders are delivered on time without sacrificing quality. - Reasonably Priced

We make sure that our prices stay competitive even though we provide high-end products. You get the most out of your investment at SGEI Forgings Pvt. Ltd. without compromising on quality.

Our Product Range at SGEI Forgings Pvt. Ltd.

We are experts in a broad variety of forged gear parts made for different sectors. Among the products we offer are:

- Spur gears

The most popular kind of gear, spur gears, are used to transfer motion between parallel shafts and have straight teeth. They are perfect for high-speed, straightforward applications. - Helical Gears

Compared to spur gears, helical gears operate more smoothly and silently because of their angled teeth. They are frequently found in heavy machinery and automobile transmissions. - Bevel Gears

Bevel gears are made to transfer motion, usually at a 90-degree angle, between intersecting shafts. They are employed in applications that need precise directional changes, such as differential drives. - Worm Gears

Worm gears, which provide high torque reduction and smooth operation, are made up of a screw-like worm and a gear that meshes with it. They are frequently found in elevators and conveyor systems. - Customized Gear Parts

We produce custom gear components that are suited to your unique needs in addition to standard gear types. Regardless of the complexity of your project, SGEI Forgings Pvt. Ltd. has the skill to complete it.

Conclusion: Forged Gear Components Manufacturer

In many different industries, forged gear components are crucial to guaranteeing the robustness, longevity, and effectiveness of machinery. Selecting SGEI Forgings Pvt. Ltd. means working with a business that is dedicated to providing premium, tailored solutions that satisfy the highest performance requirements. We are the best Forged Gear Components Exporter.

SGEI Forgings Pvt. Ltd. has the know-how and technology to offer the best forged gear components for your needs, regardless of your industry—automotive, aerospace, heavy machinery, or power generation. We’re here to support the success of your company by emphasizing accuracy, dependability, and client satisfaction.

To find out more about how we can assist with your needs for forged gear components, get in touch with us right now.