CNC Electric Screw Forgings Manufacturer

Table of Contents

Introduction

An Indian forging company, SGEI Forgings Pvt.ltd. is a top manufacturer and supplier of a variety of high-quality closed die forgings and rolled ring forgings. We have been in business for more than 50 years, and during that period we have delivered with passion, quality, and the ability to complete an order on time. Customers value our items because they perform well. We provide a variety of products, including closed die forging and rolled ring forging.

In the complex realm of manufacturing, where strength, precision, and efficiency are essential, forging serves as a fundamental element. Whether it’s the sturdy elements of heavy machinery or the fine details of aerospace components, forgings offer unmatched structural strength. However, with the evolution of industries, the creation methods must also adapt. Welcome to the age of CNC Electric Screw Forgings – a groundbreaking advancement that is reshaping the boundaries of metal forming. We are the best CNC Electric Screw Forgings Supplier.

This comprehensive article will examine the intriguing domain of CNC Electric Screw Forgings, investigating their significant influence on multiple industries, the advanced production methods used, and the considerable advantages they provide. We will also highlight a genuine leader in this sector: SGEI Forgings Pvt. Ltd., a company that has provided unmatched quality and innovation in the forging.

Understanding CNC Electric Screw Forgings

Prior to examining the details of CNC electric screw forgings, let’s take a brief look back at the basic idea of forging. Forging, a manufacturing method, involves shaping metal through localized compressive forces. Forging differs from casting, which involves pouring molten metal into a mold, and machining, which entails removing material. Instead, forging rearranges the metal’s internal grain structure to improve its strength, toughness, and fatigue resistance. This results in a component that is fundamentally more robust and long-lasting than one made using alternative techniques. We are the best CNC Electric Screw Forgings Exporter.

Why Choose SGEI Forgings Pvt. Ltd

- Unparalleled Expertise and Experience: Our team consists of engineers, metallurgists, and technicians with deep expertise and vast experience in advanced forging techniques, material science, and CNC precision manufacturing. Thanks to our combined know-how, we can take on even the most intricate forging difficulties.

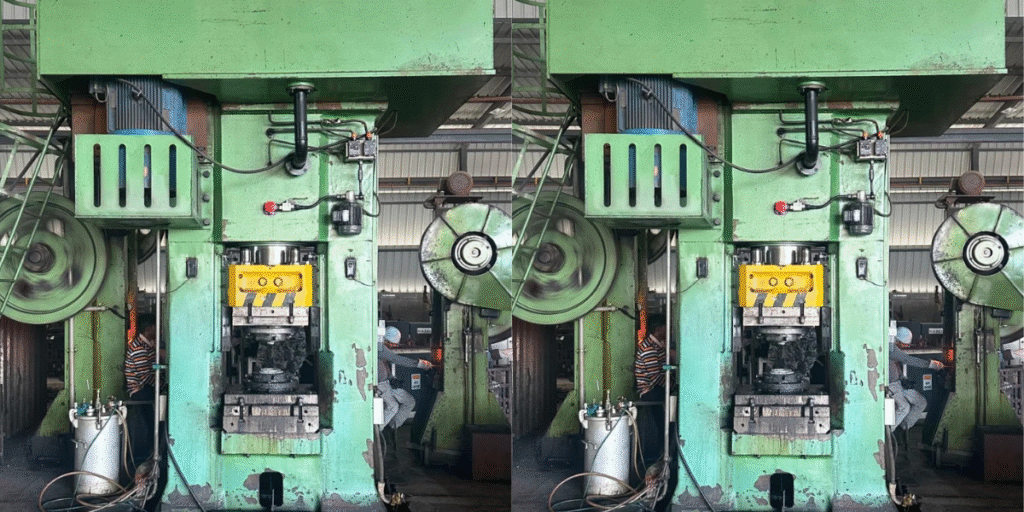

- Top-Notch Infrastructure: SGEI Forgings Pvt. Ltd. features a modern manufacturing facility with the latest CNC electric forging presses, automated handling systems, precision tooling, and advanced heat treatment capabilities. This guarantees high-quality products and effective production.

- Strict Quality Control and Assurance: At SGEI, quality is more than a mere buzzword; it is embedded in every phase of our process. We comply with rigorous international quality standards (such as ISO certifications) and employ extensive quality control measures, which include.

- Customization and Engineering Solutions: We recognize that each industry and application has distinct needs. SGEI Forgings Pvt. Ltd. stands out for its exceptional customized forging solutions. From inception to completion, our engineering team collaborates closely with clients, providing design optimization, advice on material selection, and rapid prototyping to create custom screw forgings that precisely align with their unique requirements and performance standards.

- Dedication to Innovation: The world of manufacturing is always changing, and we are changing with it. SGEI Forgings Pvt. Ltd. makes considerable investments in R&D, investigating new materials, processes, and technologies to improve our product range and uphold our competitive advantage.

- Dependability and Punctual Delivery: We recognize how crucial it is to deliver on time in the rapidly moving industries of today. Thanks to our solid production planning, streamlined logistics, and commitment to punctuality, we guarantee that your orders arrive on schedule each time—without sacrificing quality.

- Cost-Effectiveness and Value: Our focus is on quality, but we also aim to provide competitive prices while maintaining performance standards. Through our efficient processes, optimized use of materials, and long-term partnerships with suppliers, we are able to deliver exceptional value for your investment. Opting for SGEI means opting for a partner who grasps the equilibrium between expenses and excellent performance.

- Customer-Centric Approach: Our clients sit at the center of all our endeavors at SGEI Forgings Pvt. Ltd. We are committed to developing enduring relationships founded on trust, transparency, and open dialogue. You can always count on our devoted customer support team to help you with questions, technical issues, and post-sales assistance.

Applications of CNC Electric Screw Forgings

- Automotive industry: This sector is a significant consumer of forged components, with CNC electric screw forgings being crucial. The durability and fatigue resistance of forged components are vital for vehicle safety and performance, whether they are parts of the engine (like crankshafts, connecting rods, and gears), transmission system, suspension and steering assemblies, or brake system (discs and calipers). The transition to Electric Vehicles (EVs) is amplifying the need for specialty forged components for motors, batteries, and transmission systems, where precision and lightweighting are essential.

- Aerospace and Defense: In these sectors with high demands, the failure of components is not permissible. Critical components like airframe parts, landing gear, turbine blades, missile elements, and structural features for aircraft and defense vehicles utilize CNC electric screw forgings. Forged components must exhibit a high strength-to-weight ratio and integrity in this context.

- Oil & Gas Industry: Equipment used in the oil and gas sector functions under severe pressure and difficult conditions. Reliable and wear- and corrosion-resistant components such as valves, fittings, flanges, drill bits, and pump parts are made from forgings.

- Industrial Machinery: Whether it’s heavy construction equipment or agricultural machinery, the demand for durable and sturdy components is always present. CNC electric screw forgings serve as components for gears, shafts, levers, links, and other essential parts across various industrial applications.

- Power Generation: Turbines (wind and gas) components, generators, and power plant equipment must possess extraordinary strength and heat resistance. Forged components guarantee that these crucial systems function reliably.

- Marine Industry: Deck and hull structures, trimmings, joints, and various other components for marine vessels necessitate the strength of forged metals.

Table of Specifications for CNC Electric Screw Forgings

| Parameter | Specification Range |

|---|---|

| Product | CNC Electric Screw Forgings |

| Material Grades | Carbon Steel, Alloy Steel, Stainless Steel, Duplex Steel |

| Press Capacity | 1000 KN to 16000 KN |

| Dimensional Tolerance | ± 0.3 mm |

| Surface Finish | As Forged, Machined, Heat Treated, Shot Blasted |

| Maximum Diameter | Up to 300 mm |

| Maximum Length | Up to 500 mm |

| Heat Treatment Options | Normalising, Hardening & Tempering, Annealing |

| Testing Methods | MPI, UT, Hardness Test, Chemical & Mechanical Analysis |

| Production Capacity | 5000+ Forgings per Month |

Types of CNC Electric Screw Forgings

1. Open Die Forgings

- In open die forging, the metal billet is placed between flat or simple-shaped dies, leaving the sides open for deformation. CNC Electric Screw Presses enhance accuracy and reduce operator dependency in open die forging.

Applications: Shafts, discs, rings, large blocks, and custom shapes for heavy industries.

2. Closed Die (Impression Die) Forgings

- Closed die forging involves compressing the heated metal within shaped dies to form precise components. CNC control ensures consistent cavity filling and excellent dimensional accuracy.

Applications: Automotive components, aerospace parts, gears, crankshafts, and connecting rods.

3. Ring Forgings

- Ring forging is the process of shaping a metal ring by applying pressure through CNC-controlled electric screw presses. This ensures uniform material properties and dimensional accuracy.

Applications: Bearings, flanges, pressure vessel components, and aerospace rings.

4. Precision CNC Forgings

- Precision forgings involve creating high-tolerance, complex-shaped components with minimal machining requirements. CNC control improves repeatability and optimizes material flow.

Applications: Automotive precision parts, valve components, turbine blades, and hydraulic fittings.

5. Large Component Forgings

- With the ability to handle high-capacity presses, CNC Electric Screw Forgings are ideal for large and heavy components used in critical applications.

Applications: Heavy machinery parts, railway components, marine equipment, and wind energy parts.

Conclusion

The development of forging technology, especially with the advent of CNC electric screw forgings, represents a major advancement in manufacturing. This technology is essential for industries requiring high-performance components due to its ability to attain unmatched precision, improve material properties, increase efficiency, and lower costs. We are the best Best CNC Electric Screw Forgings Manufacturer.

SGEI Forgings Pvt. Ltd., with its established history spanning more than 50 years, exemplifies the effectiveness of merging traditional know-how with advanced technology. Their steadfast dedication to quality, wide-ranging product offerings, and adoption of cutting-edge manufacturing techniques such as CNC electric screw forging reinforce their status as a reliable and prominent manufacturer in the forging sector. For companies in search of dependable, top-notch, and accurately designed forged components, SGEI Forgings Pvt. Ltd. is the clear preferred partner, helping to mold the future with each flawlessly forged piece.