CNC Finished Parts Manufacturer

Introduction

An Indian forging company, SGEI Forgings Pvt.ltd. is a top manufacturer and supplier of a variety of high-quality closed die forgings and rolled ring forgings. We have been in business for more than 50 years, and during that period we have delivered with passion, quality, and the ability to complete an order on time. Customers value our items because they perform well. We provide a variety of products, including closed die forging and rolled ring forging.

In the contemporary manufacturing environment, which moves at a breakneck speed, precision, efficiency, and dependability are not merely fashionable terms – they are crucial to achieving success. The days when every component was shaped manually, depending only on human skill and often resulting in inconsistencies, are long gone.

CNC Machining has today become the leader, thanks to its revolutionary technology.If you have ever been curious about how complex, precisely formed metal and other material components are produced for items ranging from your vehicle to medical devices, the answer frequently involves a CNC Finished Parts Manufacturer. It is here that firms such as SGEI Forgings Pvt. Ltd. become involved, utilizing their know-how to mold the future of production. We are the best CNC Finished Parts Supplier.

What Exactly Are CNC Finished Parts

Picture this: you want to carve out of a metal block an object with a highly specific shape, such as a complex gear for machinery or a fine part for a medical device. A skilled craftsman of the past would meticulously cut, drill, and shape the material using a variety of tools. The process was slow, and even the most skilled hands could make minor mistakes, resulting in variations in the final product. This is where CNC comes into play. The term CNC refers to Computer Numerical Control. Imagine it as a highly intelligent robotic arm that adheres to extremely precise directives from a computer program. We are the best CNC Finished Parts Exporter.

Why Choose SGEI Forgings Pvt. Ltd

- More than 50 Years of Incomparable Experience & Knowledge: This goes beyond a mere figure; it reflects their profound expertise and development in manufacturing. Having spent more than 50 years in the business, SGEI Forgings Pvt. Ltd. offers an unmatched comprehension of materials, manufacturing methods, engineering difficulties, and quality assurance. This extensive experience leads to outstanding outcomes in their CNC machining processes, enabling them to foresee possible problems and provide the best solutions. They have witnessed everything and gained knowledge from all of it.

- A Steadfast Dedication to Quality It’s Innate: For SGEI Forgings Pvt. Ltd., quality goes beyond being a mere departmental focus; it is a basic tenet that steers each and every move. They realize that even the smallest defect in a completed component can greatly affect your product’s performance and safety. From inspecting raw materials to verifying final dimensions, they implement stringent, multi-tiered quality control processes at every stage of production. This commitment is further strengthened by their internal laboratory testing and analysis capabilities, which guarantee that each component not only has an attractive appearance but also performs perfectly according to international standards.

- Cutting-edge Precision Engineering: SGEI Forgings Pvt. Ltd. commits to and utilizes sophisticated CNC equipment, comprising multi-axis milling and turning centers. A group of proficient engineers and technicians who specialize in programming, tooling, and optimizing machining processes operate these state-of-the-art machines. By harnessing state-of-the-art technology and human know-how, they are able to reliably meet the stringent tolerances and complex shapes required by contemporary industries, producing components with outstanding surface quality and precise dimensions.

- Unique Forging-to-Finish Integration: This sets us apart. Unlike many CNC machine shops that are purely focused on machining, SGEI Forgings Pvt. Ltd. possesses a unique and powerful advantage due to its deep roots in forging. They can combine forging processes (which yield exceptionally strong, durable, and near-net initial shapes) with precise CNC machining in a seamless manner. This provides a thorough, all-encompassing manufacturing solution. By managing both stages, they can streamline material flow, improve mechanical properties through forging, and attain final precision with CNC, often yielding components for their clients that are stronger, lighter, and more economical.

- Customer-Centric Partnership Approach: SGEI Forgings Pvt. Ltd. goes beyond being a mere supplier; they aspire to serve as an extension of your engineering and manufacturing team. They embrace a genuine customer-centric strategy, collaborating intimately with their clients from the early stages of concept and design consultation (providing valuable Design for Manufacturability – DFM insights) to prototype creation and final delivery. They are dedicated to grasping your particular requirements, offering clear communication, and guaranteeing that the completed components adhere to technical specifications while also playing a crucial role in the success and efficiency of your projects. Their track record of punctual delivery of complete orders is indicative of their esteem.

- Strong Quality Assurance and Laboratory Capabilities: Their dedication to quality is backed by thorough quality assurance procedures. This encompasses ongoing inspections during the process, final dimensional assessments with state-of-the-art metrology tools, and even laboratory testing of material characteristics and structural soundness. This careful method guarantees that each individual component departing from their facility conforms to both your distinct specifications and the most stringent industry standards.

Applications of CNC Finished Parts

- Oil & Gas Industry: This sector exemplifies a domain where large, durable, and precisely machined components are essential. SGEI Forgings Pvt. Ltd. offers essential CNC finished components that endure extreme pressures, temperatures, and corrosive conditions, ranging from large wellhead parts and pipeline fittings to detailed components for drilling rigs, subsea equipment, and valves. With our expertise, we guarantee trustworthy and secure operations within this crucial industry.

- Heavy Machinery & Construction: Consider the massive gears in excavators, the sturdy shafts in cranes, or the structural parts of large earthmoving machines. These machines function under immense stress, and for safety and durability, their large components must be manufactured to perfection. SGEI Forgings Pvt. Ltd. provides the necessary precision and strength for these high-demand applications.

- Power Generation (Turbines & Generators): The core of power plants, be they conventional or renewable, depends on large, complexly engineered parts such as turbine blades, shafts, and casings. The flawless production of these large components is crucial for the efficiency and safety of these systems. We have the ability to reliably produce energy.

- Marine & Shipbuilding: The large propellers, rudder components, engine parts, and structural elements for ships and offshore platforms require both substantial size and high precision. These components need to endure the corrosive effects of the marine environment and tremendous forces. SGEI Forgings Pvt. Ltd. possesses the capability to produce these essential components.

- Mining: The equipment employed in mining activities is frequently of enormous size, intended to fracture and transport great volumes of earth and rock. This encompasses large gears, components of crushers, and heavy-duty axles, all of which necessitate the strength and precision that large CNC machining offers.

- Medical Devices: With regard to human health, precision is essential. CNC machining creates essential medical devices, surgical implements, implants (such as hip and knee replacements), and parts for diagnostic tools. It is essential for the effectiveness of the device and the safety of the patient that the finishing be sterile and that the dimensions be exact.

- Electronics: CNC is involved in the production of complex connectors, heat sinks, and perfectly fitting housings for even our small electronic devices.

Table of Specifications CNC Finished Parts

| Product Name | Material | Tolerance | Surface Finish | Maximum Size | Applications |

|---|---|---|---|---|---|

| CNC Turned Shafts | Alloy Steel, Mild Steel, SS | ±0.01 mm | Polished/As Required | Up to 500 mm Length | Automotive, Industrial Machinery |

| CNC Milled Components | Stainless Steel, Aluminium | ±0.02 mm | Machined/Coated | 500 x 500 mm | Aerospace, Railways |

| CNC Forged & Machined Parts | Carbon Steel, Alloy Steel | ±0.03 mm | Painted/Galvanized | As per Client Drawing | Oil & Gas, Power Sector |

| Custom Precision Components | Brass, Copper, SS, Aluminium | ±0.005 mm | As Required | As per Custom Design | Medical, Defense, Aerospace |

| CNC Drilled Components | Mild Steel, Alloy Steel | ±0.02 mm | Machined | Up to 500 mm | Construction, Heavy Engineering |

Benefits of CNC Finished Parts

- Super Accurate and Precise: This is the most significant advantage! Parts produced by CNC machines can have variations that are remarkably small. This ensures that the completed product will always be identical to the computer design. When it comes to items such as medical implants or aircraft components, even the slightest variation can be crucial. CNC guarantees that accuracy.

- Always Reliable, Always Uniform: After being programmed, the CNC machine will produce the same parts repeatedly, regardless of whether the quantity is 10 or 10,000. This is extremely crucial for producing many items where each component must be identical, such as in automobiles or electronics. There’s no need for you to worry about minor differences between sections.

- Complex Shapes Simplified: CNC machines are capable of producing shapes and details that would be extremely challenging or even unfeasible to achieve manually. Consider minute apertures, complex bends, or extremely delicate designs—CNC manages these effortlessly, providing engineers with novel design options.

- Accelerated Production: Due to their lack of fatigue, CNC machines can operate non-stop, frequently around the clock. As a result, they can manufacture components at a speed far exceeding that of conventional techniques, which aids businesses in expediting product delivery and satisfying considerable demand.

- Reduced Waste, Decreased Expenses: Due to the high precision of CNC machines, they generate less waste of raw material. When there are fewer mistakes, it results in a reduced need to discard parts. This cuts down on expenses for materials and lowers total production costs over time.

- Safer for Workers: As the machines perform the exact cutting and shaping, human workers are distanced from hazardous tools. This significantly enhances workplace safety.

- Compatible with Various Materials: CNC machines offer great versatility. They are capable of working with a diverse array of materials, such as various metals (including steel, aluminum, and brass), plastics, and even wood. This renders them beneficial for a multitude of items spanning different industries.

Types of CNC Finished Parts

1. CNC Machined Shafts

- Used extensively in automotive, aerospace, and machinery applications. These precision-engineered shafts are made to exact dimensions and finish specifications.

2. CNC Turned Components

- These are rotational parts manufactured through CNC turning processes. Commonly used in engines, pumps, and mechanical systems.

3. CNC Milled Parts

- Produced using CNC milling machines, these parts include brackets, housings, plates, and custom mechanical parts.

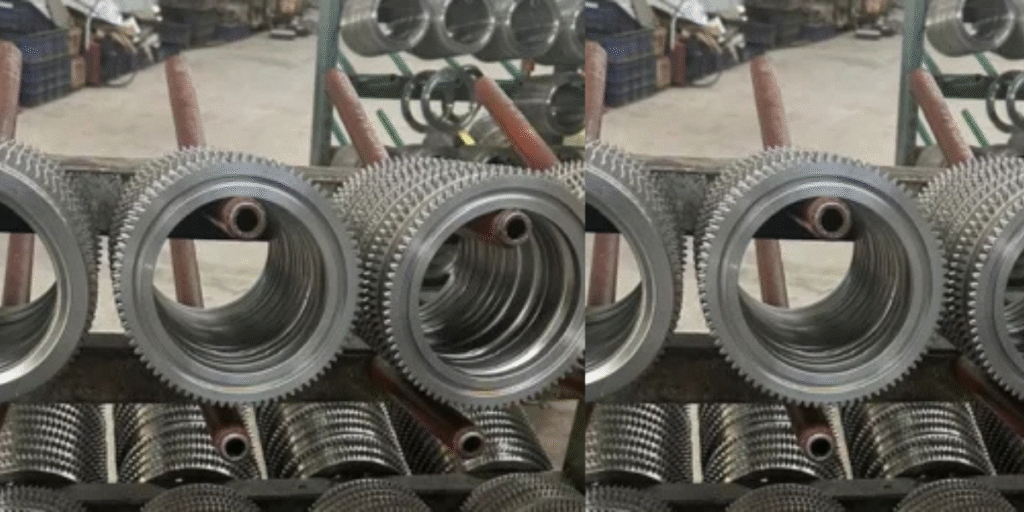

4. CNC Forged Components

- High-strength components made by combining CNC machining with forging techniques. Ideal for heavy-duty applications.

5. CNC Bushes and Sleeves

- Used in automotive suspension systems, industrial machinery, and electrical equipment.

6. CNC Couplings

- Precision couplings for connecting rotating shafts in mechanical assemblies.

7. CNC Gears and Sprockets

- Essential for power transmission applications, these gears and sprockets are made with accurate tooth profiles and finishing.

8. CNC Valves and Fittings

- Custom-designed valves and pipe fittings for industries such as oil & gas, water treatment, and chemical processing.

Conclusion

The manufacturing sector is constantly changing, and the demand for components with high precision is increasing. Joining forces with a trustworthy CNC Finished Parts Manufacturer involves more than simply having a part produced; it concerns guaranteeing that your products are reliable, effective, and future-proof. We are the best Best CNC Finished Parts Manufacturer.

SGEI Forgings Pvt. Ltd. is a paragon of quality in this industry. With their remarkable experience of more than 50 years, cutting-edge CNC capabilities, and unwavering commitment to quality and customer satisfaction, they stand out as an exceptional partner for all your precision manufacturing requirements. They don’t merely produce components; they create flawlessness, guaranteeing your triumph.