Cross Transmission Forging Manufacturer

Introduction

An Indian forging company, SGEI Forgings Pvt.ltd. is a top manufacturer and supplier of a variety of high-quality closed die forgings and rolled ring forgings. We have been in business for more than 50 years, and during that period we have delivered with passion, quality, and the ability to complete an order on time. Customers value our items because they perform well. We provide a variety of products, including closed die forging and rolled ring forging.

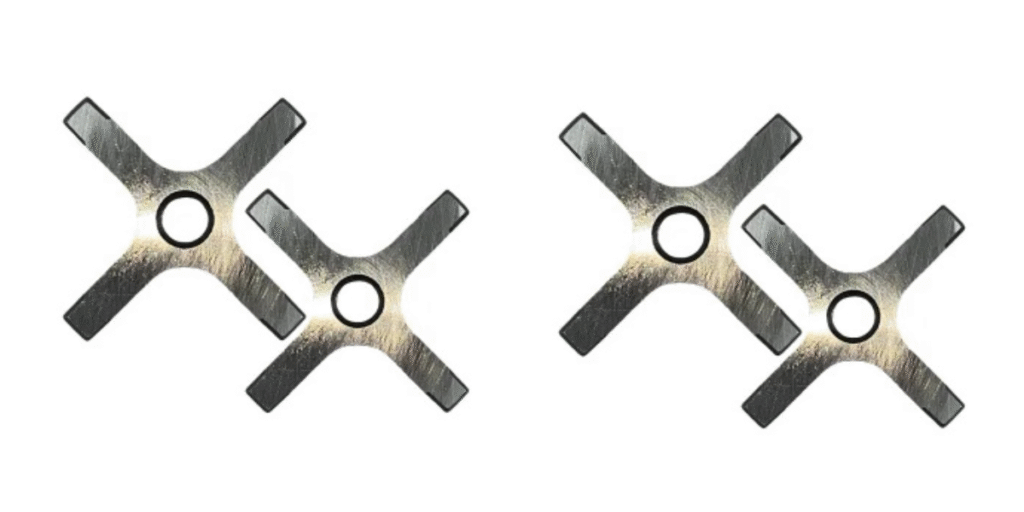

Have you ever thought about what allows a car to change gears seamlessly, a tractor to haul heavy weights, or a wind turbine to rotate effectively? A vital element of the transmission system underpins all these remarkable engineering accomplishments. Cross transmission forgings lie at the heart of many sturdy transmission systems.Although they may be out of sight, these components are laboring without rest. They manage enormous forces and guarantee that energy is conveyed exactly from the engine to the wheels or between different sections of a machine. To put it simply, they are the unacknowledged champions that facilitate motion and energy in innumerable uses. We arev the best Cross Transmission Forging Supplier.

What Exactly is a Cross Transmission Forging

Envision a sophisticated metal object, crafted with astonishing accuracy and intended to endure immense pressure and deterioration. In essence, that is what a cross transmission forging is. These components are usually produced via a method known as forging, in which metal is heated to a high temperature and then formed using localized compressive forces. Imagine a blacksmith shaping heated metal with a hammer – forging represents a highly sophisticated iteration of that age-old trade. We are the best Cross Transmission Forging Provider.

Why Choose SGEI Forgings Pvt. Ltd

- Unmatched Expertise and Experience: SGEI Forgings has a team of highly skilled engineers and technicians with extensive knowledge of different forging processes and material properties, thanks to their years of experience in the forging industry. We comprehend the detailed requirements of cross transmission components and can address designs that are highly complicated.

- Top-Tier Infrastructure: Our production site features next-generation forging presses, hammers, heat treatment furnaces, and state-of-the-art inspection tools. This enables us to uphold exceptional quality control while attaining high production efficiency.

- Commitment to Quality: We place quality at the heart of all our actions. Throughout the manufacturing process, from sourcing raw materials to conducting final inspections, we comply with rigorous quality management systems and adhere to international standards. By concentrating on quality, we guarantee that each cross transmission departing from our facility is sturdy, dependable, and operates without a hitch.

- Customization and Flexibility: We recognize that each client has distinct needs. SGEI Forgings provides a high level of customization, collaborating closely with clients to design and produce cross transmissions that exactly match their specifications, including for niche applications. We can accommodate orders of both small and large quantities thanks to our adaptable production capabilities.

- Competitive Pricing: Although we always maintain quality, SGEI Forgings is dedicated to providing competitive prices. We can offer solutions that are economical yet high-performing and long-lasting, thanks to our optimized supply chain and efficient manufacturing processes.

- On-time delivery: We acknowledge how crucial it is to deliver on time in the rapidly moving world of industry today. With our optimized production planning and logistics, we guarantee timely delivery of your orders, which reduces downtime and enhances your operational efficiency.

- Client-Centric Approach: Our clients are the focal point of our operations at SGEI Forgings. We are committed to establishing enduring relationships that rely on trust, transparency, and open dialogue. You can always rely on our devoted customer support team to help you with your questions and offer technical assistance.

- Concentration on Innovation: The industrial environment is in a state of constant change. SGEI Forgings keeps up with the newest developments in forging technology and materials science, and is always working to enhance and innovate our processes and products.

Applications Cross Transmission Forging

- Automotive Industry: This is likely the most evident application. Cross transmission forgings are utilized in manual and automatic transmissions, differentials, transfer cases, and drive shafts of vehicles ranging from the smallest compact cars to heavy-duty trucks. Consider gear blanks, spline shafts, universal joint yokes, and differential cases – all essential parts for a vehicle to operate smoothly and reliably.

- Agriculture: Tractors, harvesters, and other farming equipment require tremendous power and robust durability. Cross transmission forgings are essential components of their gearboxes, PTO (Power Take-Off) systems, and drive train assemblies, allowing them to endure challenging field conditions and substantial loads.

- Construction Equipment: Bulldozers, excavators, loaders, and cranes depend on strong transmission systems to transport heavy materials and function in harsh conditions. They are able to provide the required power and endure continuous mistreatment thanks to forged parts in their transmissions, axles, and drivelines.

- Industrial Machinery: Numerous industrial applications employ intricate transmission systems, ranging from conveyor systems and pumps to power generation equipment and textile machinery. Cross transmission forgings offer the strength and precision necessary for dependable and efficient functioning in these challenging environments.

- Aerospace: Even if the volume may be reduced, the demands for precision and reliability in aerospace are of utmost importance. Forged parts are utilized in aircraft gearboxes and power transmission systems, where complete integrity is essential.

Specifications of Cross Transmission Forgings

| Parameter | Specification |

|---|---|

| Product | Cross Transmission Forgings |

| Forging Weight Range | 0.5 Kg to 25 Kg |

| Hardness | As per customer requirement (28-40 HRC typically) |

| Heat Treatment | Normalizing, Tempering, Hardening |

| Testing | Ultrasonic Testing, MPI, Hardness, Dimensional Inspection |

| Tolerance Standards | As per ISO 2768 or customer specification |

| Surface Finish | Shot Blasted, Machined, Painted |

| Delivery | 3-4 Weeks (depending on quantity & design) |

Advantage of Cross Transmission Forgings

- Top-of-the-line Production Facility: We have made substantial investments in advanced technology. We have modern forging presses, induction heating systems, advanced material handling robotics, and precision machining capabilities at our plant. This enables us to manufacture components of superior quality and extraordinary uniformity, even in large quantities.

- Unmatched Proficiency and Experience: Forging goes beyond machines; it’s a matter of knowledge and experience. We have a team of engineers, metallurgists, and technicians with decades of collective experience in forging complex transmission components. They are highly skilled professionals. We comprehend the complexities of material properties, die design, heat treatment, and quality control that are essential for success.

- Comprehensive In-House Capabilities: SGEI provides a complete, integrated solution that encompasses everything from initial design and simulation to forging, heat treatment, machining, and final inspection. As a result of this vertical integration, our clients benefit from more stringent quality control, shorter lead times, and smooth project management. You are not working with several suppliers; you are receiving an efficient service from a single trustworthy provider.

- Thorough Quality Control: Quality is the foundation of SGEI Forgings. We comply with the highest international quality standards. We possess in-house testing facilities that offer magnetic particle inspection (MPI), ultrasonic testing (UT), hardness testing, impact testing, and metallurgical analysis. Each and every component is subjected to thorough inspections so as to guarantee that it conforms to your specifications and the demands of the industry or surpasses them. We pledge to achieve “zero defects.”

- Customization and Design Collaboration: Our production goes beyond standard components. SGEI flourishes when faced with challenges. From the design phase onward, we collaborate closely with our clients, providing expert guidance on material selection, ideal grain flow, and design for manufacturability (DFM). Our engineering team utilizes cutting-edge simulation software to refine designs, guaranteeing optimal performance and cost efficiency.

- Dedication to Innovation: The manufacturing industry is in a state of continuous evolution, and we are evolving alongside it. SGEI Forgings is committed to ongoing enhancement and innovation. We regularly investigate new materials, forging techniques, and automation technologies to improve our processes and provide even greater value to our customers.

- Scalability and Large Volume Production: SGEI Forgings possesses the capability and flexibility to fulfill your requirements, whether you need small quantities of specialized parts or large-scale production at high volumes for your assembly operations. We guarantee punctual delivery, even for the most ambitious projects, thanks to our solid infrastructure and streamlined processes.

- Customer-Focused Approach: Our clients are central to all our activities at SGEI. We are committed to establishing enduring partnerships founded on trust, transparency, and reliable performance. Our devoted customer service team is always prepared to help, offer updates, and deal with any issues quickly. When you succeed, we succeed.

Types of Cross Transmission Forgings

1. Universal Joint Cross Forging

A Universal Joint (U-joint) Cross Forging connects two shafts allowing them to rotate at different angles. It is commonly used in vehicle drivelines and agricultural equipment.

Applications:

- Automotive propeller shafts

- Heavy commercial vehicles

- Tractors and harvesters

2. Spider Cross Forging

Also known as a spider forging, it connects multiple shafts in a cross arrangement. These are designed to bear high torque and heavy operational loads.

Applications:

- Industrial machinery

- Transmission systems in construction equipment

3. Differential Cross Forging

Used in the differential systems of automobiles, these forgings manage the speed difference between the driving wheels while turning.

Applications:

- Passenger vehicles

- Commercial transport vehicles

4. PTO (Power Take-Off) Cross Forging

These are specially designed for transferring power from tractors or heavy-duty engines to auxiliary equipment like harvesters, drills, or compressors.

Applications:

- Agricultural equipment

- Earth-moving machinery

Conclusion

The cross transmission is a testament to engineering ingenuity, enabling the seamless transfer of power in countless applications. The process of forging these critical components is a specialized field, demanding precision, expertise, and an unwavering commitment to quality. The resulting forged parts offer unparalleled strength, durability, and reliability, making them the preferred choice for demanding environments. We are the best Best Cross Transmission Forging Manufacturer.

As industries continue to evolve and demand more efficient and robust machinery, the role of expert cross transmission forging manufacturers becomes even more critical. Companies like SGEI Forgings Pvt. Ltd. are at the forefront of this evolution, leveraging advanced technology and deep industry knowledge to deliver forged solutions that power the world forward. When performance, longevity, and precision matter, trust the strength of forged components and the expertise of SGEI Forgings Pvt. Ltd. for your cross transmission needs.