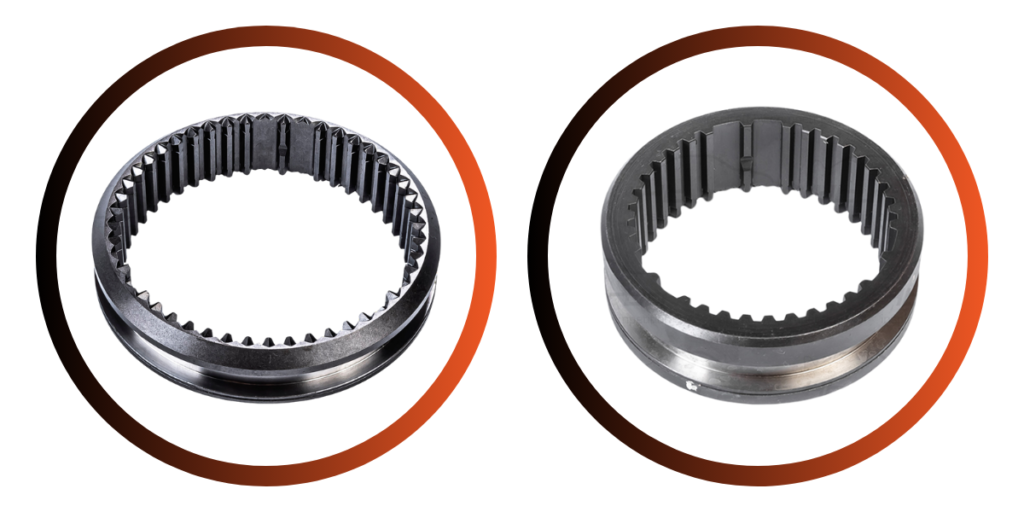

Shifter Sleeve Forgings Manufacturer

Shifter Sleeve Forgings Manufacturer/Shifter Sleeve Forgings Supplier/Shifter Sleeve Forgings Exporter/Shifter Sleeve Forgings Supplier in Jamshedpur/Shifter Sleeve Forgings/

Table of Contents

Introduction

Since its Inception in 1966, our Parent company Drop Forging (India) has been Vendors to Prominent companies in India. SGEI Forgings Pvt. Ltd. is an Indian Forging Company and are among the prominent manufacturers and suppliers of a wide range of optimum quality Closed Die Forgings and Rolled Ring Forgings. We are the best Shifter Sleeve Forgings Manufacturer.

Durability and quality are critical factors in the production of precision parts for the automotive sector. The shifter sleeve is one such essential component of the automotive transmission system, and it is imperative that these parts are manufactured with the highest care and skill. SGEI Forgings Pvt. Ltd., a top manufacturer of shifter sleeves, guarantees the creation of premium shifter sleeves that adhere to the highest industry standards. The significance of shifter sleeve forgings, their production process, and the reasons SGEI Forgings is the preferred supplier of these crucial auto components will all be covered in greater detail in this article.

What is a Shifter Sleeve?

An essential component of a car’s manual transmission system is a shifter sleeve. It helps the driver shift into the appropriate gear by connecting the shifter to the gears. By locking the gear into position and facilitating seamless and effective gear changes, the shifter sleeve improves the overall performance of the vehicle. Usually constructed from premium steel, it goes through a forging process to guarantee strength, accuracy, and durability.

The Role of Shifter Sleeve Forgings

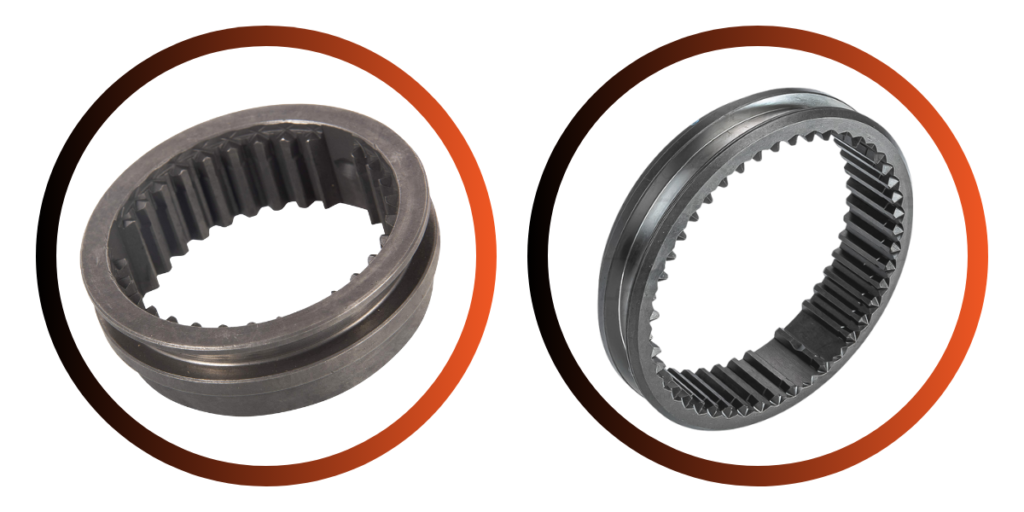

Compressive forces are used in the manufacturing process of forging to shape metal. Forging is a preferred technique for shifter sleeves because it can improve the material’s mechanical qualities, making it stronger and more dependable for long-term use. By strengthening the metal’s grain structure, the forging process lowers the possibility of flaws, fractures, or weaknesses in the part.

The raw material is heated to a predetermined temperature and then shaped with different kinds of presses or hammers. This guarantees that the finished product is highly accurate and resilient to the demands of daily driving. Because shifter sleeve forgings must withstand the continuous wear and tear of shifting gears, their longevity and functionality depend heavily on the material and manufacturing method used.

How are Shifter Sleeve Forgings Manufactured?

There are several crucial steps involved in the production of shifter sleeve forgings. Every shifter sleeve is expertly crafted at SGEI Forgings Pvt. Ltd. thanks to a methodical and well-defined process.

- Selection of Materials

Choosing the appropriate material is the first stage in the forging process. Shifter sleeves are usually made of high-quality steel alloys because of their strength, resilience to wear, and durability. The choice of material is crucial since it has an immediate impact on the shifter sleeve’s functionality and longevity. - Warming

After being chosen, the material is heated to a particular temperature to increase its malleability and facilitate shaping. Additionally, by optimizing the material’s grain structure, the heating process adds to the component’s overall strength. - Forging

Presses or hammers are used to shape the heated material during the forging process. In order to create the desired shape of the shifter sleeve, the material is pushed into a die or mold. To guarantee the component’s strength and accuracy, this step is essential. - Hardening and Cooling

The shifter sleeve is meticulously cooled following the forging procedure. To prevent thermal stress, which can cause cracks or other material flaws, this is done gradually. The component goes through a hardening process after cooling to increase its resilience to wear and tear. - Finishing and Machining

The shifter sleeve undergoes a number of machining procedures to obtain its final shape and dimensions after it has been forged and hardened. To make sure the part satisfies the necessary requirements, this involves turning, grinding, and polishing. Examining the component for flaws or imperfections is another aspect of this step. - Control of Quality

Quality control is a crucial component of our manufacturing process at SGEI Forgings Pvt. Ltd. Each shifter sleeve is carefully examined for flaws, cracks, and correct dimensions. To make sure every component satisfies the highest quality standards, we employ sophisticated testing techniques like visual inspections, magnetic particle testing, and ultrasonic testing.

Why Choose SGEI Forgings Pvt. Ltd.: Best Shifter Sleeve Forgings Manufacturer

One reputable company in the production of shifter sleeve forgings is SGEI Forgings Pvt. Ltd. We are the best Shifter Sleeve Forgings Supplier in Jamshedpur. We are the go-to option for customers in the automotive sector for the following reasons:

- Knowledge and Experience

SGEI Forgings Pvt. Ltd. has years of experience in the forging business and is qualified to create premium automotive parts, such as shifter sleeves. Our highly qualified personnel and cutting-edge production methods guarantee that every product satisfies the strictest industry requirements. - Superior Materials

We are aware that the final product is greatly influenced by the quality of the raw material. For our shifter sleeve forgings, we only source the best steel alloys and other materials because of this. Our dedication to excellence starts at the very beginning of the production process. - Accurate Production

With the help of cutting-edge equipment and tools, our modern manufacturing facilities can produce shifter sleeves with remarkable accuracy. To guarantee that every component fits precisely and performs as intended, we closely monitor every little detail. - Tailored Solutions

We at SGEI Forgings Pvt. Ltd. are aware that each client may have particular needs. To address the unique needs of our clients, we provide tailored solutions. We can modify our forging procedure to precisely match your requirements, whether they involve a particular material grade, size, or shape. - Prompt Delivery

We are aware of how crucial it is to fulfill deadlines in the automotive sector. We therefore put a lot of effort into making sure that every order is delivered on schedule without sacrificing quality. Your shifter sleeve forgings will arrive when you need them thanks to our effective production procedures and logistics. - Economical Remedies

We work hard to provide our customers with competitive pricing without sacrificing quality. We are able to offer cost-effective solutions without sacrificing product quality thanks to our effective supply chain management and manufacturing procedures. - Dedication to Sustainability

Sustainable manufacturing methods are important to us at SGEI Forgings Pvt. Ltd. Utilizing energy-efficient procedures and recycling materials wherever feasible are two ways we try to reduce our impact on the environment. Our sustainability initiatives guarantee that our goods are not only of the highest caliber but also considerate of the environment.

Applications of Shifter Sleeve Forgings

There are several uses for shifter sleeve forgings in the automotive sector. They are crucial in the following important areas:

- Manual Transmissions

In manual transmissions, shifter sleeves are an essential part that facilitates smooth and effective gear changes. They are a crucial component of the car’s drivetrain since they guarantee that the right gear is engaged and locked into position. - Heavy-Duty Vehicles

Additionally, heavy-duty vehicles like trucks, buses, and construction equipment use shifter sleeves. Forged shifter sleeves are perfect for enduring the heavy loads and challenging conditions that these vehicles are known for, and they are necessary for transmission components that are strong and permanent. - Performance Vehicles

Precision is essential in high-performance vehicles, like racing and sports cars. Smooth and dependable performance at high speeds is ensured by forged shifter sleeves, which offer the strength and durability required for rapid and accurate gear changes. - Electric Cars

The need for dependable transmission parts, such as shifter sleeves, is only increasing as electric vehicles gain popularity. Some transmission systems for electric vehicles use forged shifter sleeves to guarantee efficient and seamless gear engagement.

Conclusion: Shifter Sleeve Forgings Manufacturer

In order to guarantee seamless gear changes and dependable vehicle performance, shifter sleeve forgings are crucial parts of automotive transmission systems. SGEI Forgings Pvt. Ltd., a manufacturer of shifter sleeves, is dedicated to creating precision-engineered, long-lasting, and high-quality shifter sleeves for a variety of uses. Automotive manufacturers seeking dependable transmission components choose us because of our experience, cutting-edge manufacturing techniques, and dedication to quality. We are the best Shifter Sleeve Forgings Exporter.

Regardless of whether you require standard or custom shifter sleeve forgings, SGEI Forgings Pvt. Ltd. has the know-how and capacity to provide the ideal solution. Get in touch with us right now to find out more about our offerings and how our premium shifter sleeve forgings can help your company.